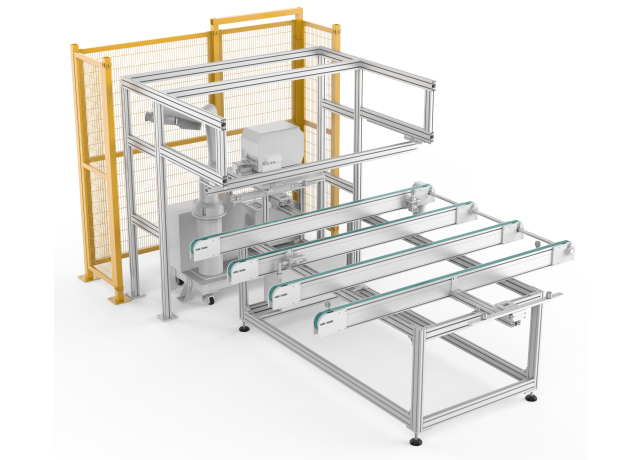

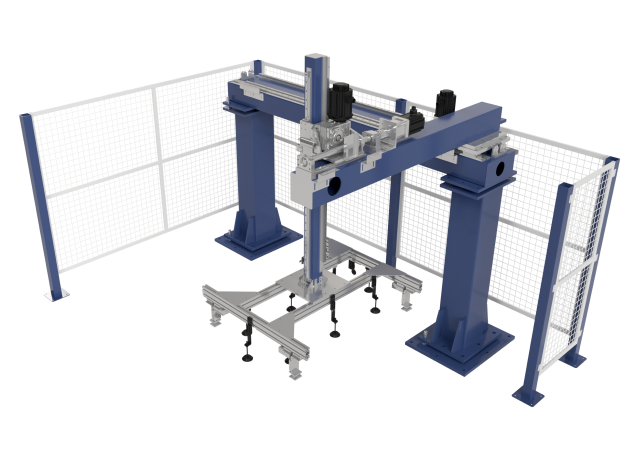

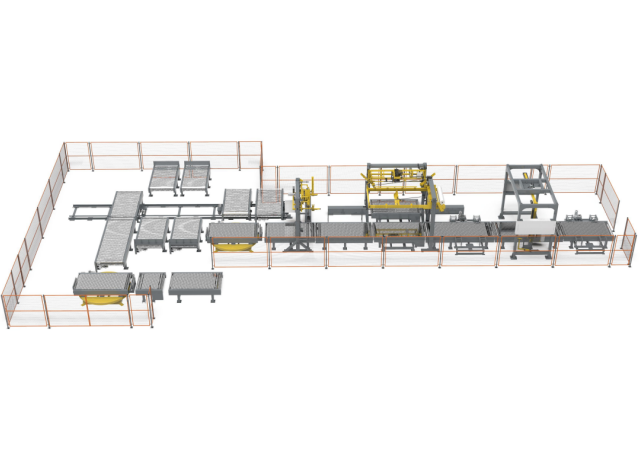

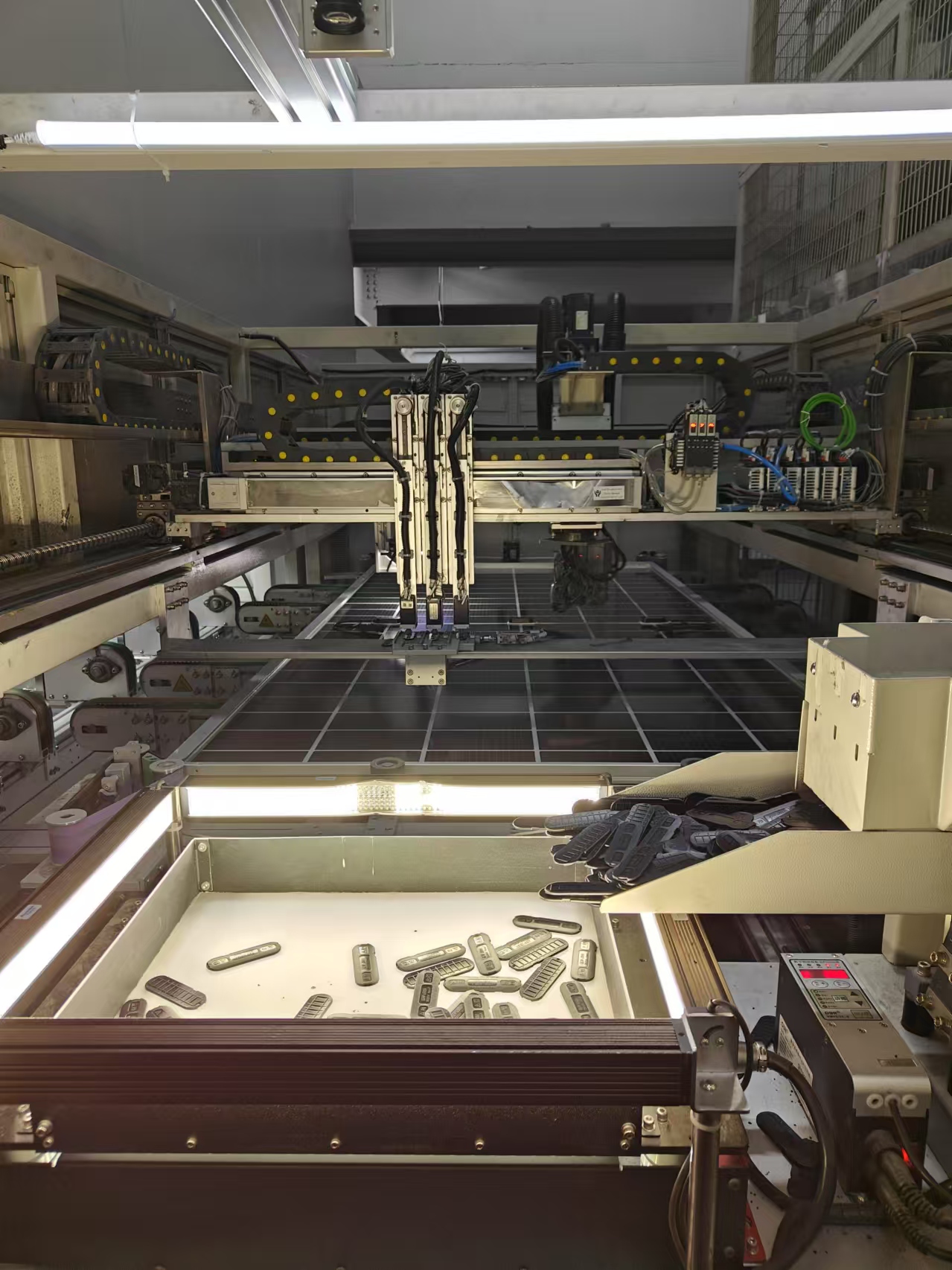

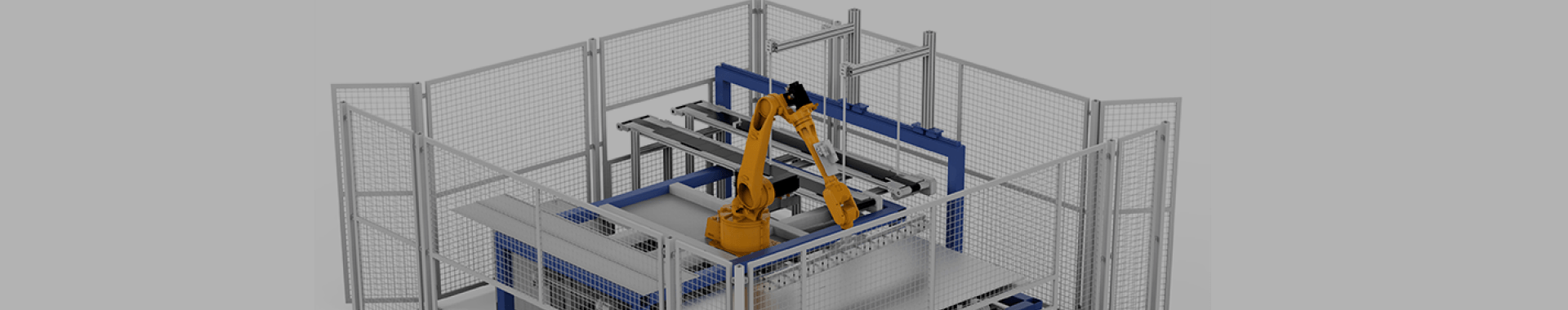

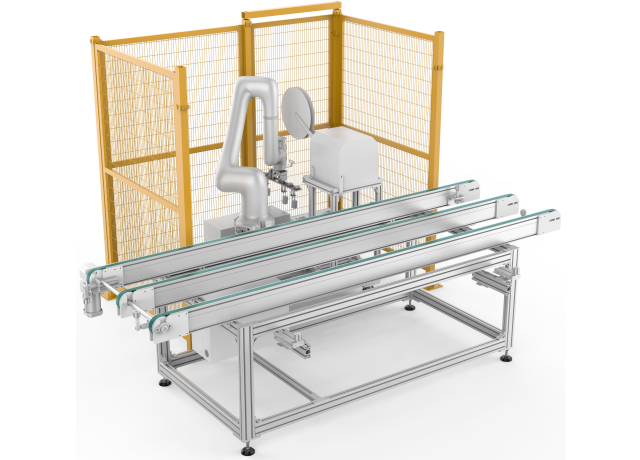

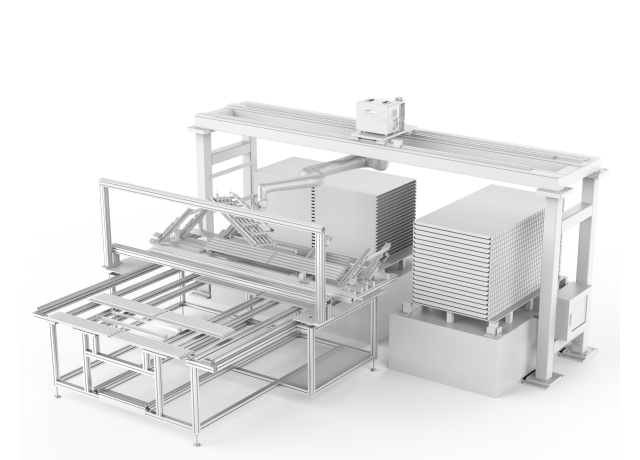

LAMINATOR POSITIONING FRAME LOADING SYSTEM

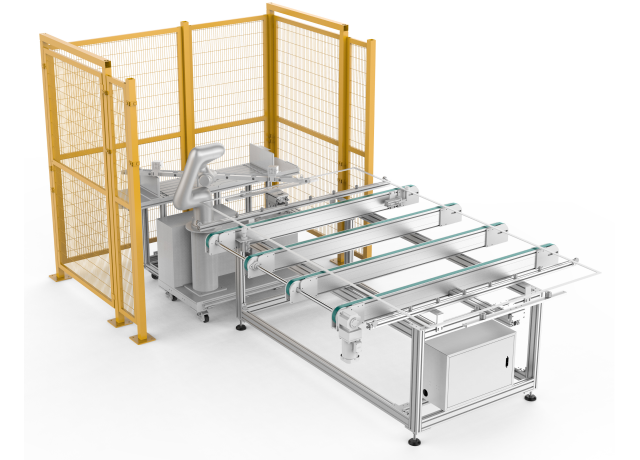

LAMINATOR POSITIONING FRAME UNLOADING SYSTEM

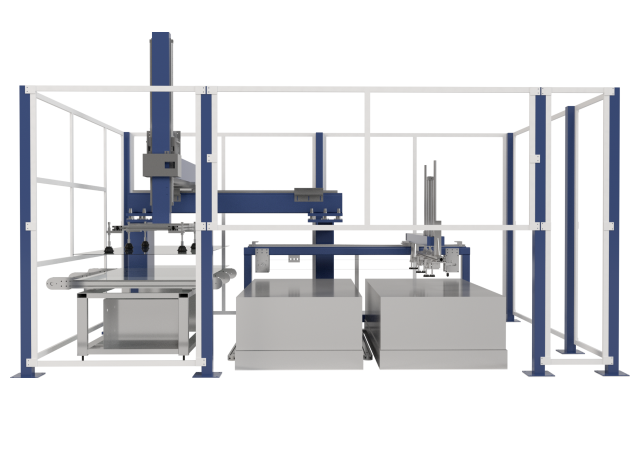

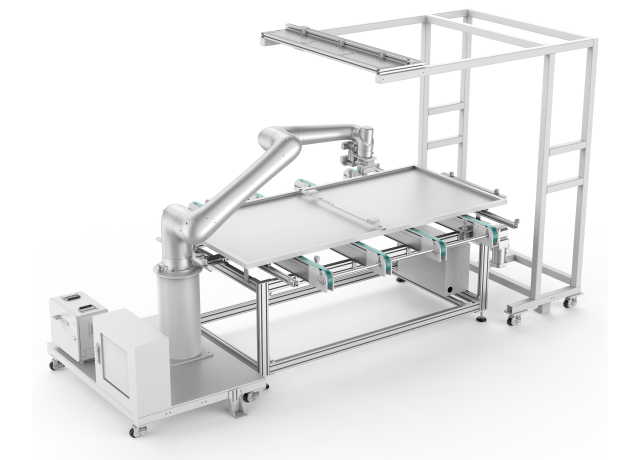

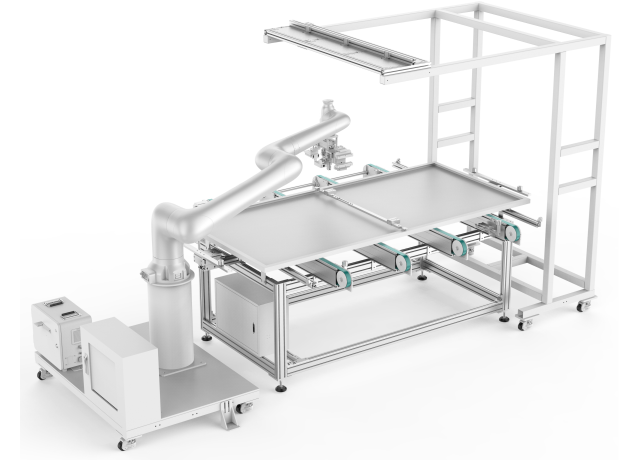

ROBOT TAKE TEFLON+BUSBAR LEADING STRAIGHT

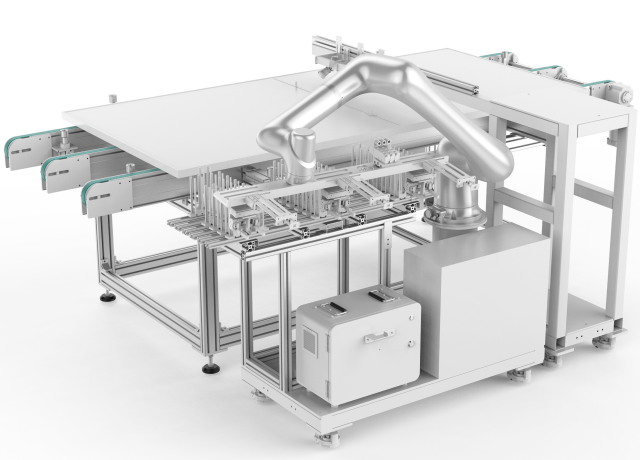

ROBOT PLACING TEFLON+BUSBAR BENDING

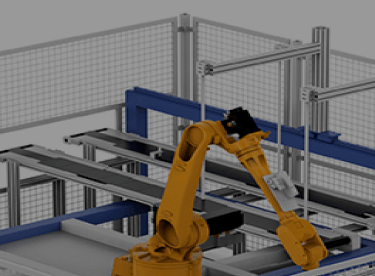

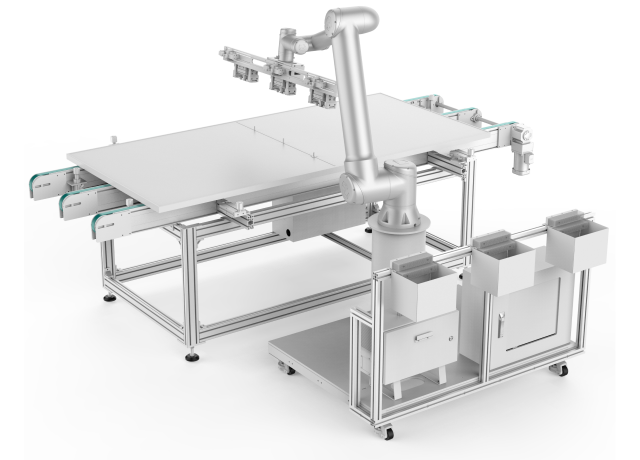

THE ROBOT LOADING THE FRAMING

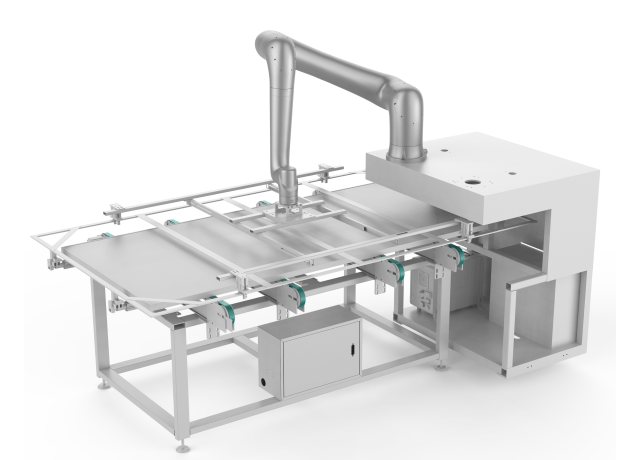

Automatic GLASS LOADING MACHINE

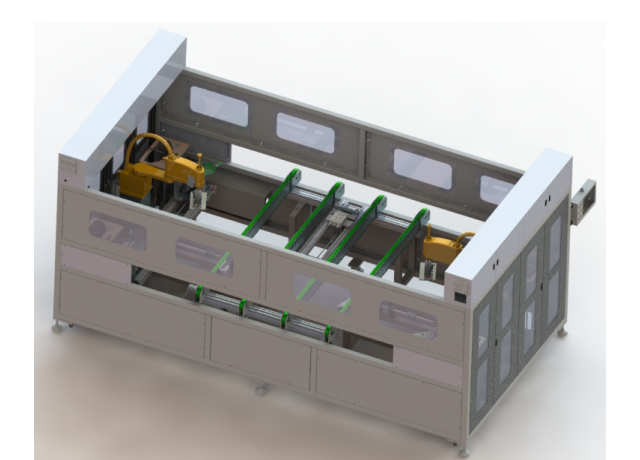

FULL AUTO SOLDERING BUSSING STATION

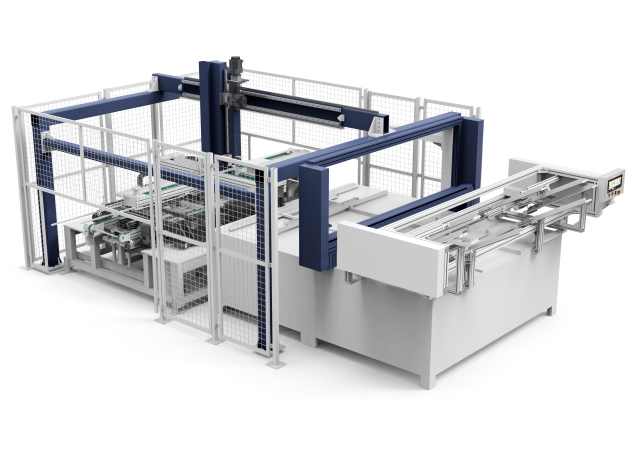

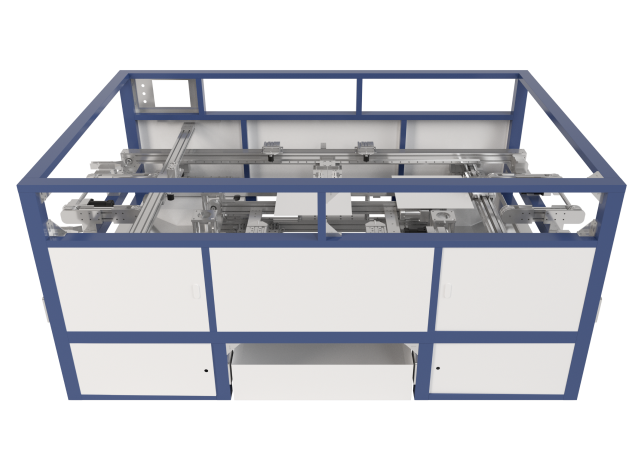

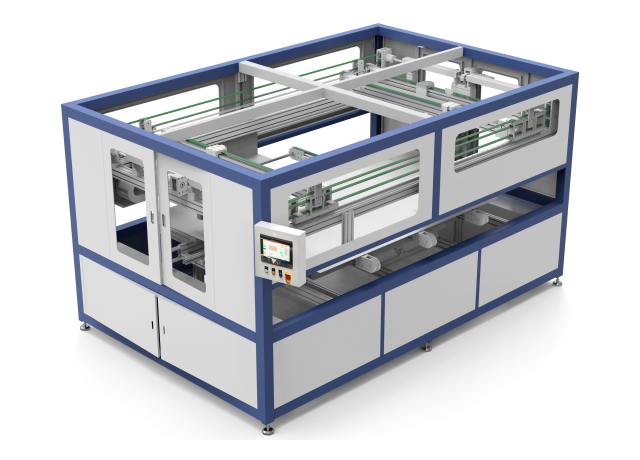

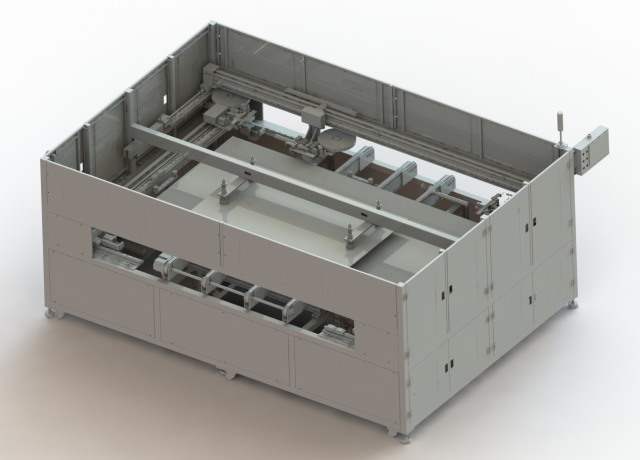

AUTOMATIC FRAMING & GLUE-FILLING INTEGRATED MACHINE

AUTO CORNER PROTECTOR INSERTING MACHINE

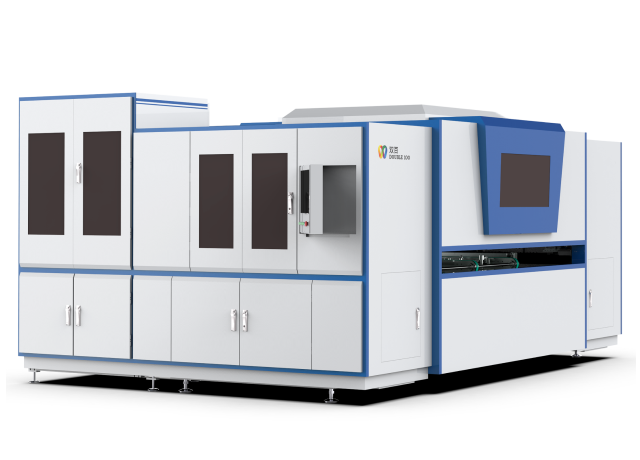

DOUBLE GLASS LAMINATING MACHINE

DOUBLE GLASS REPAIR TRANSPLANT MACHINE

JUNCTION BOX COVERING MACHINE

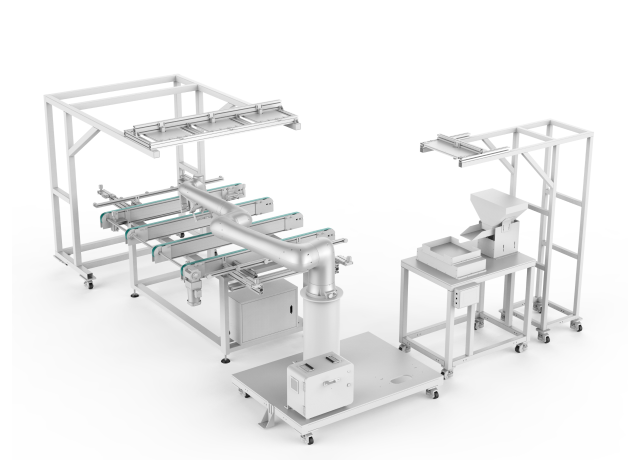

AUTO EVA / TPT CUTTING & LAYUP MACHINE

Standalone Equipment

Independent equipment

.png)