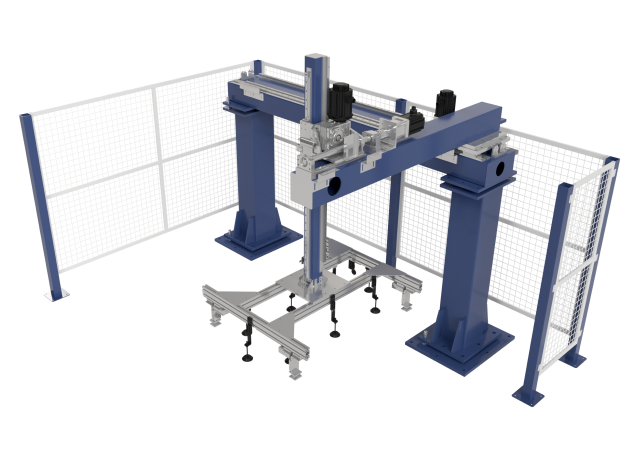

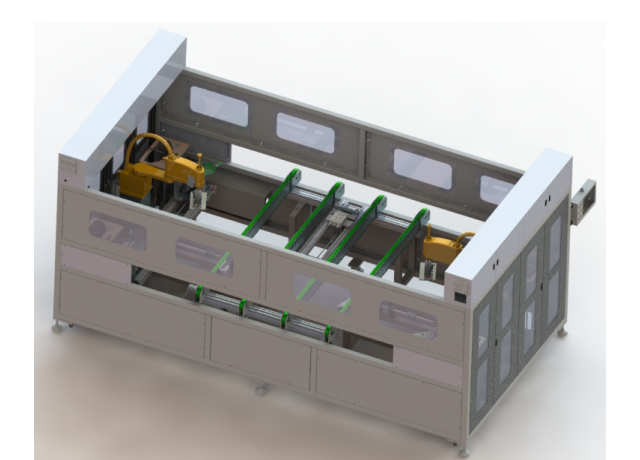

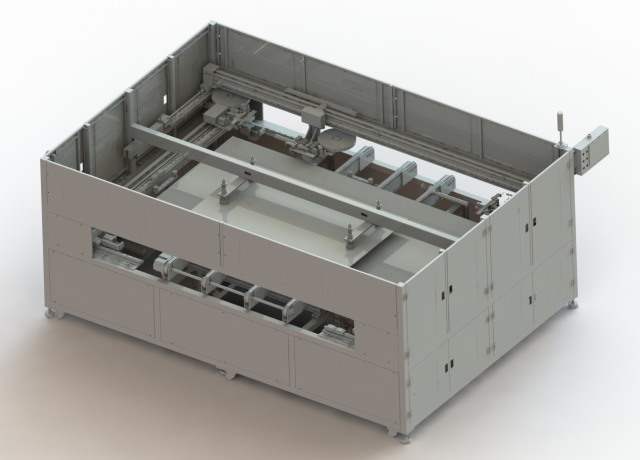

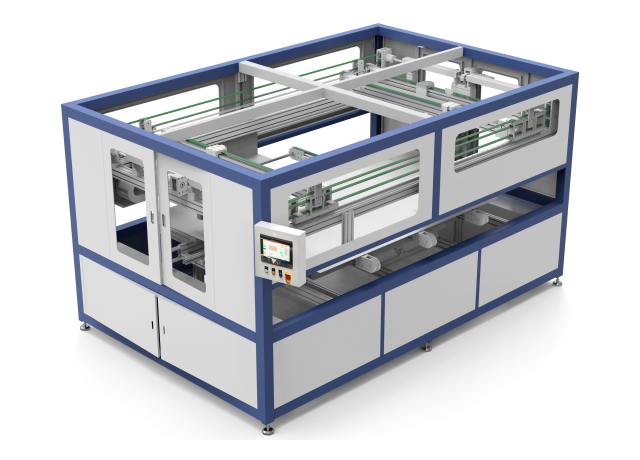

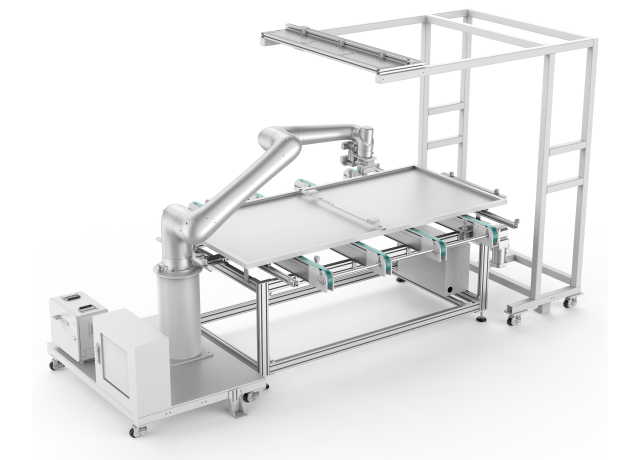

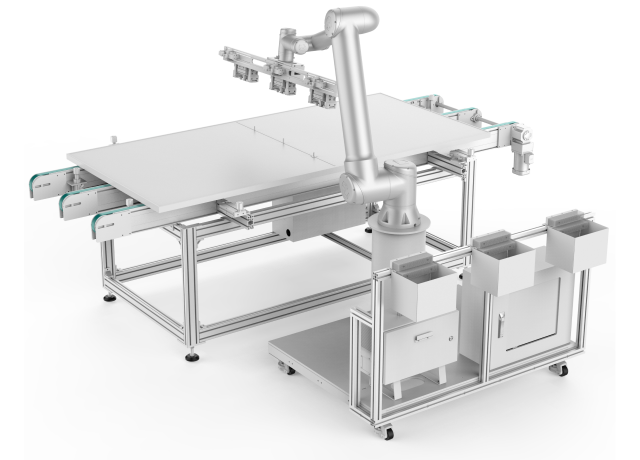

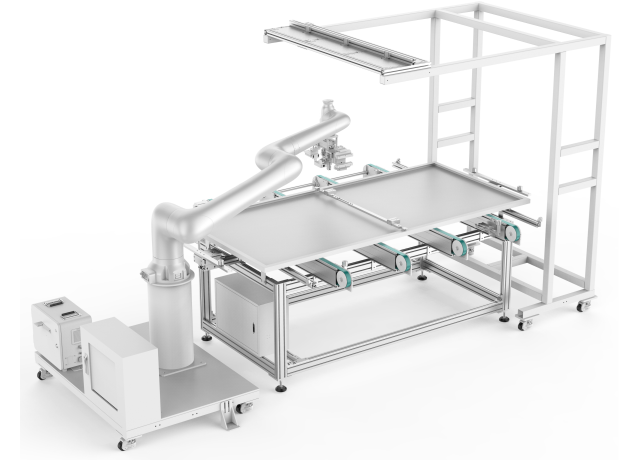

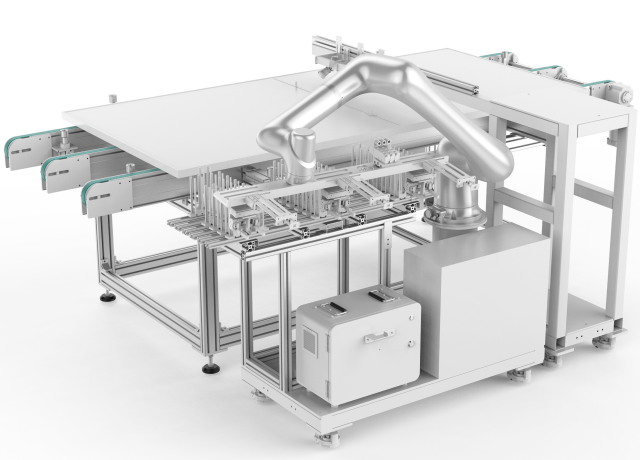

Structural Features

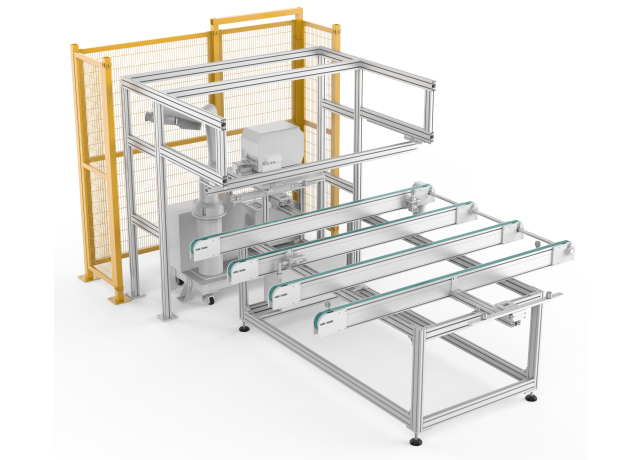

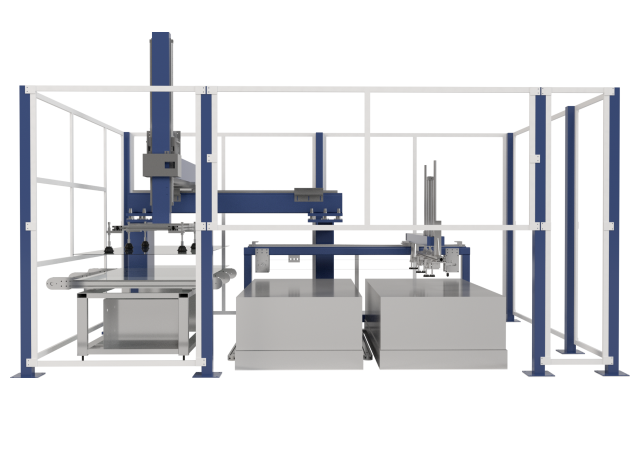

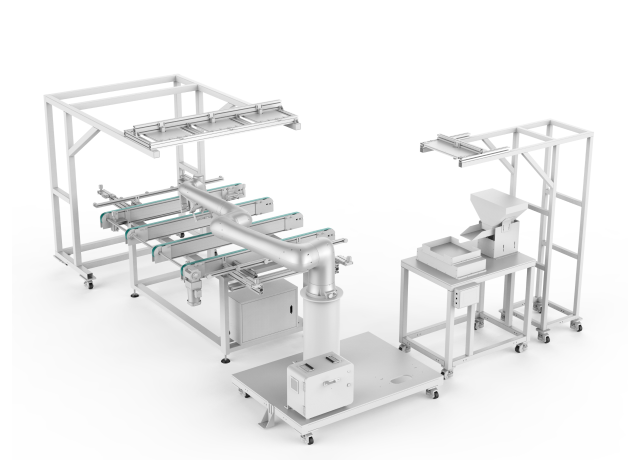

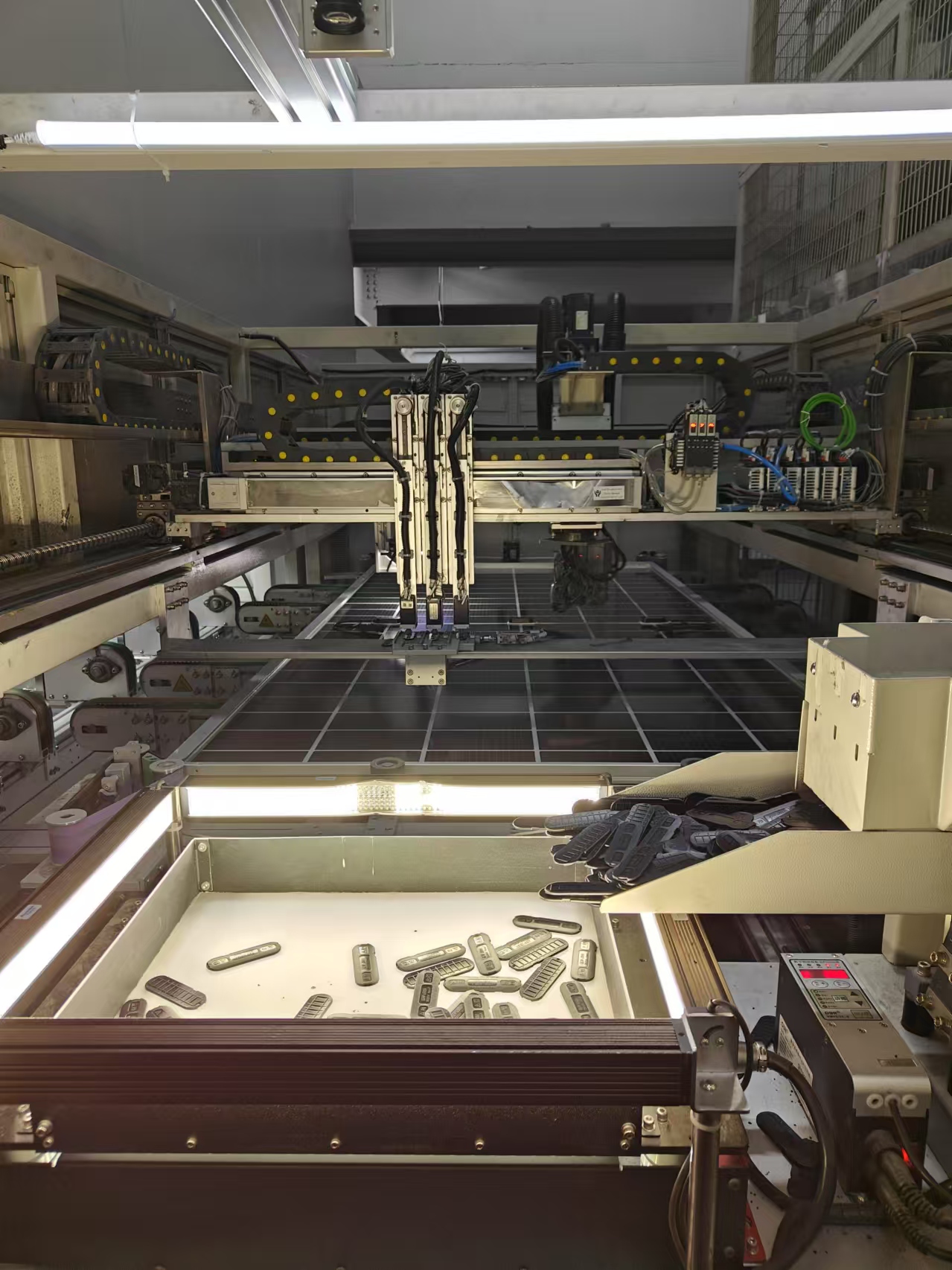

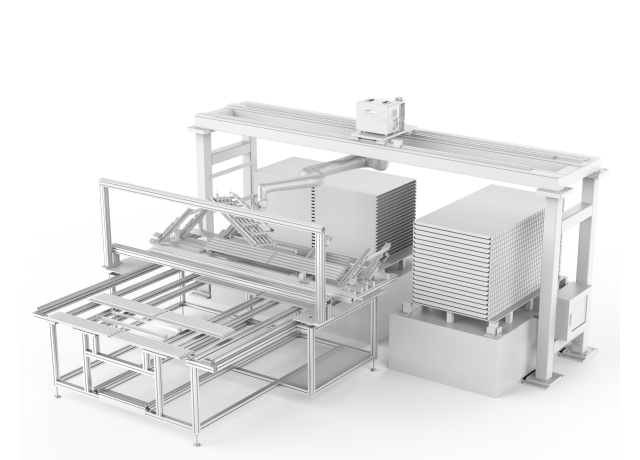

The overall structure includes a glass alignment system, a tape application system, and a vacuum system.

The servo motor drives the tape mechanism, providing high speed and high precision.

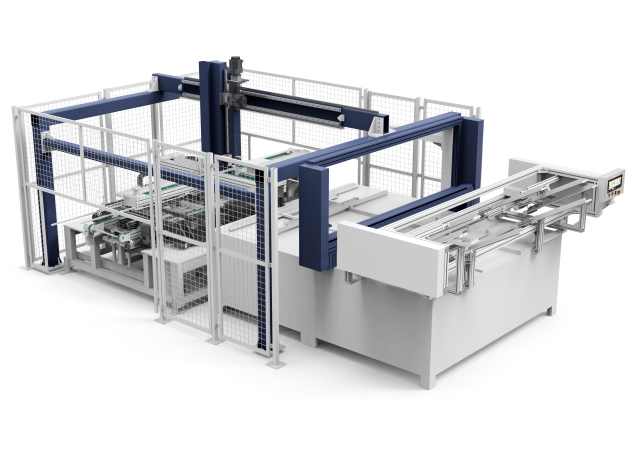

The patented pressing device not only ensures the stability of the adhesion but also effectively prevents the cracking and damage of the batteries.

The steel frame structure prevents shaking of the tape head during high-speed operations.

Reasonably configured sliding rails allow for quick glass replacement, making it easy for customers to switch versions.

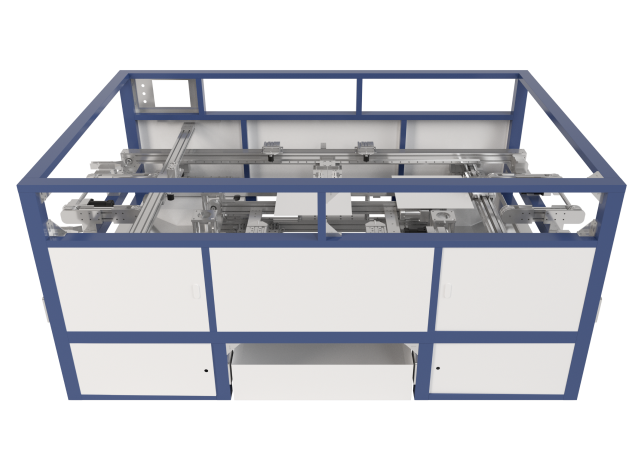

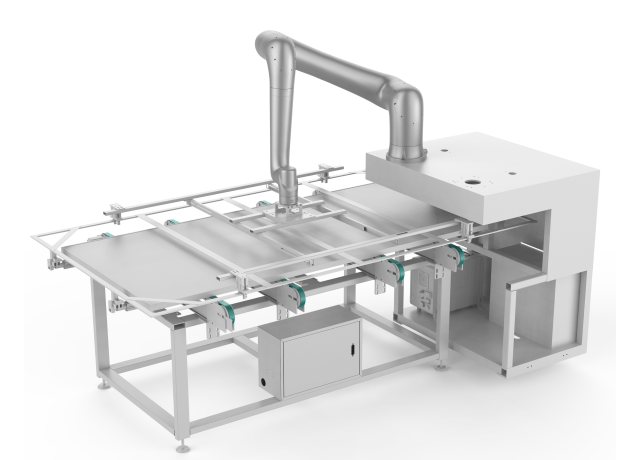

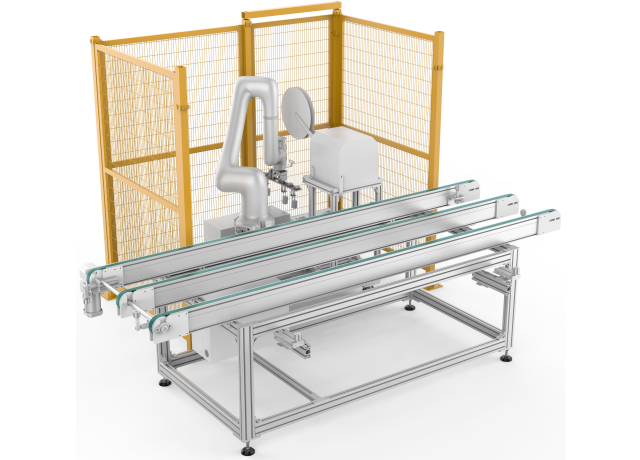

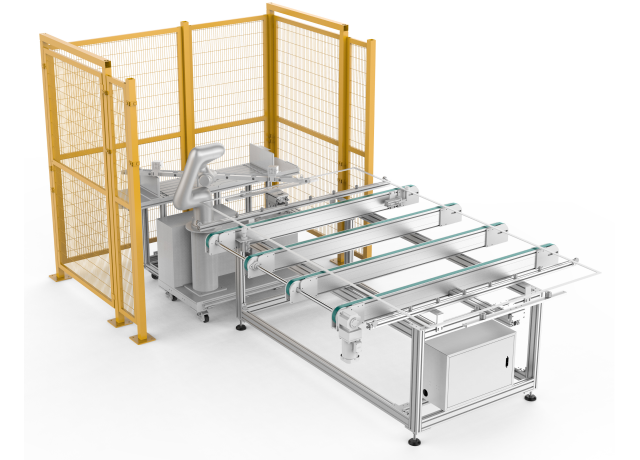

Structural Features

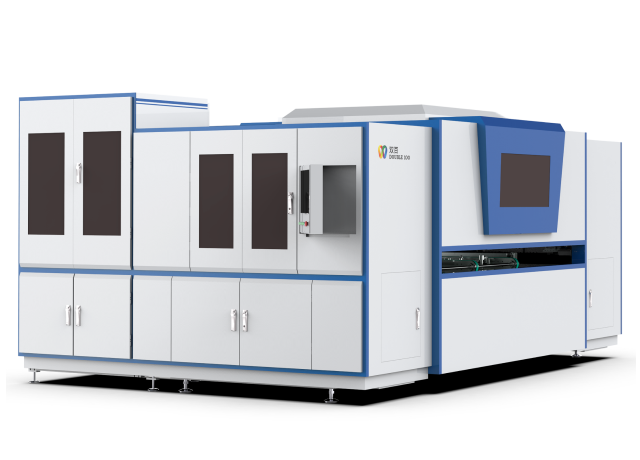

Operating Voltage

AC380V, Three-phase Five-wire, 50/60Hz

Rated Power

4KW

Operating Air Pressure

0.6-0.8MPa

Average Air Consumption

≥220L/min

Tape Type

Length ≥ 15mm-25mm, Width ≥ 5mm, Suitable for 3V-1 Standard Hardness Tape

Tape Width

Suitable for tape width 10-14mm

Drive Mode

Servo Drive

Control Mode

PLC+HMI+Servo Control

Robot Arm Positioning Accuracy

±0.2mm

Adhesion Accuracy

±1.5mm

Module Size

Length (1630-2650mm) x Width (950-1450mm)

Cycle Time

14 seconds

Overall Dimensions

3360*2260*1750mm

Total Weight

Approximately 2000kg

.png)