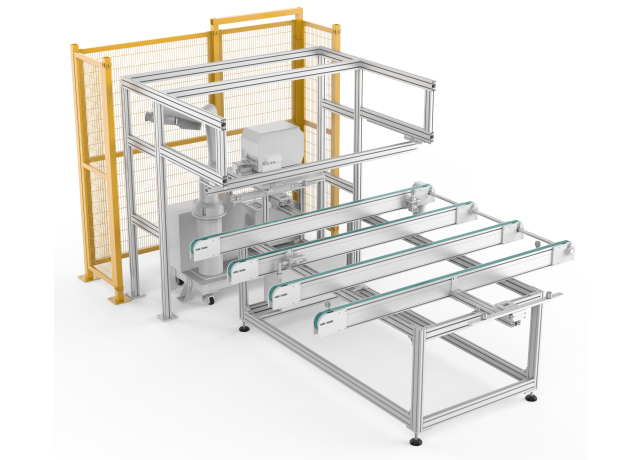

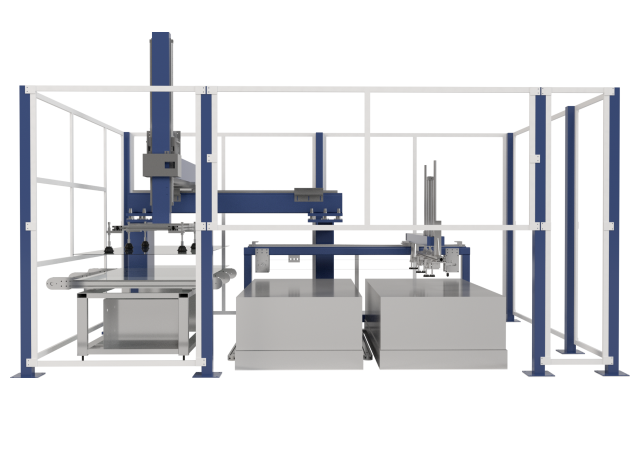

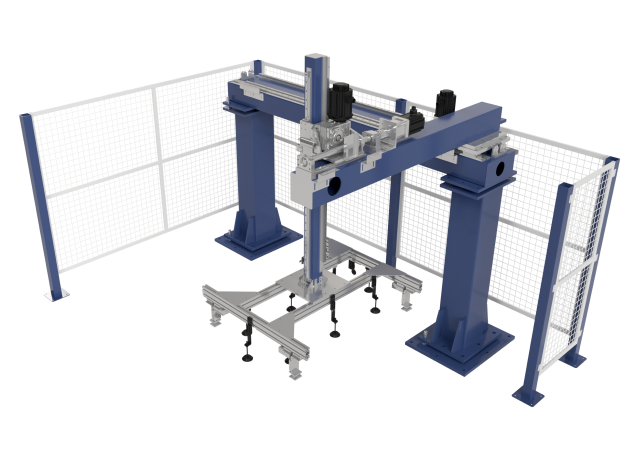

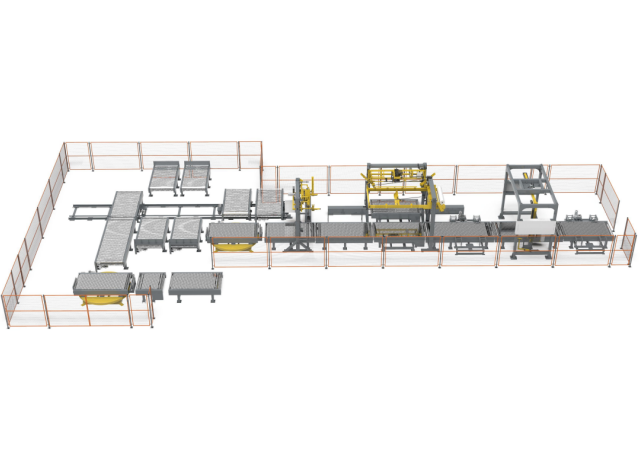

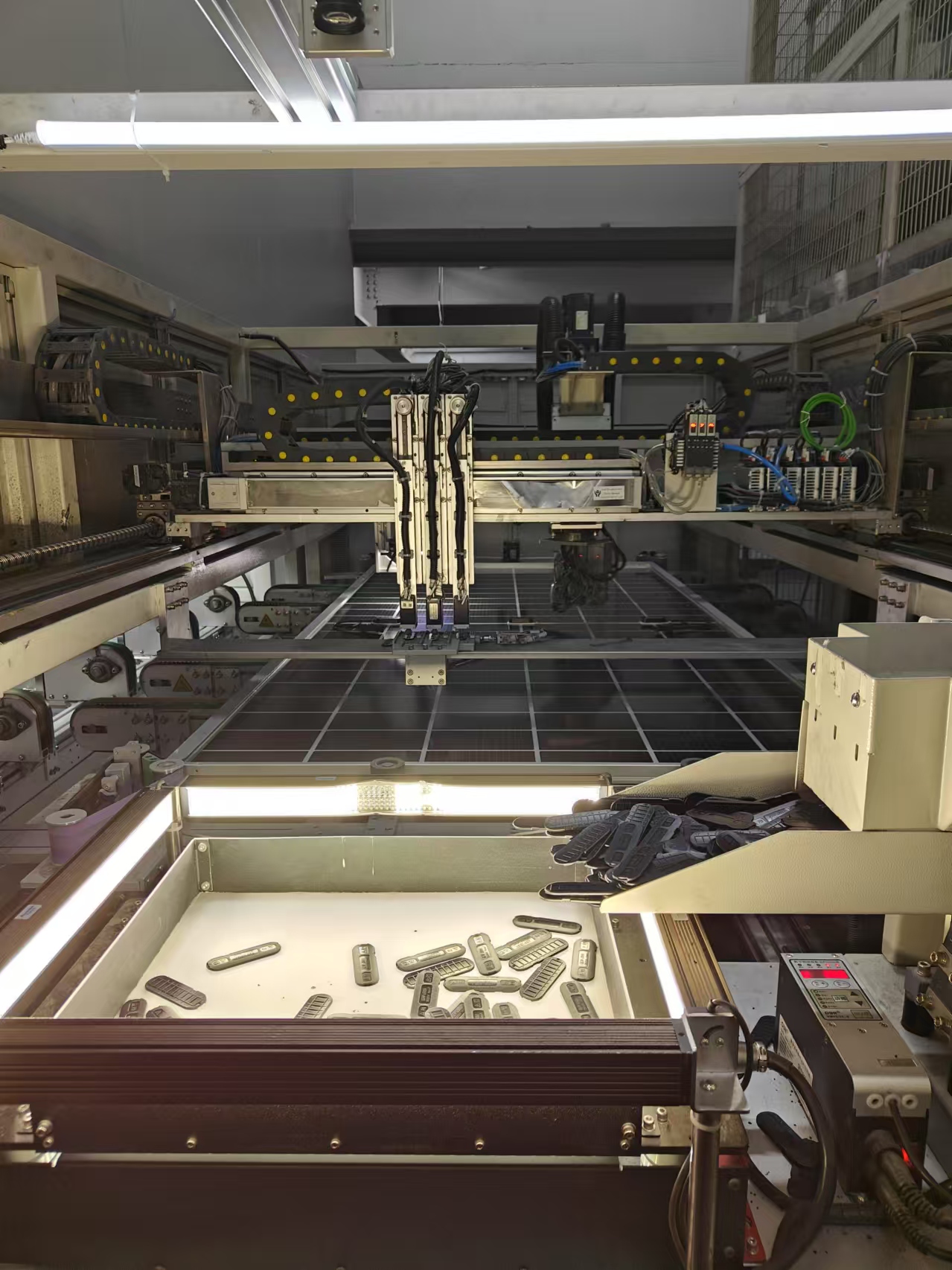

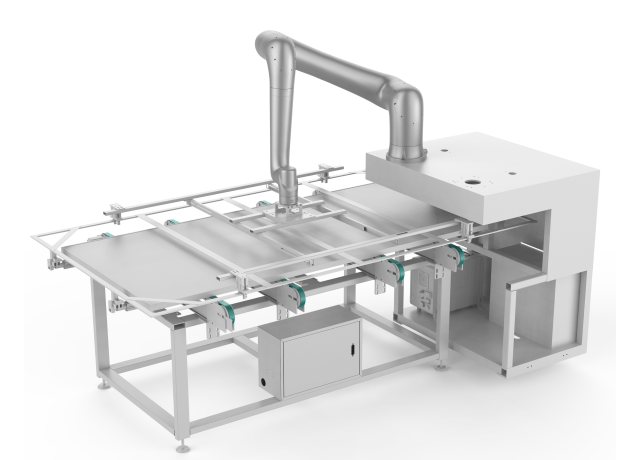

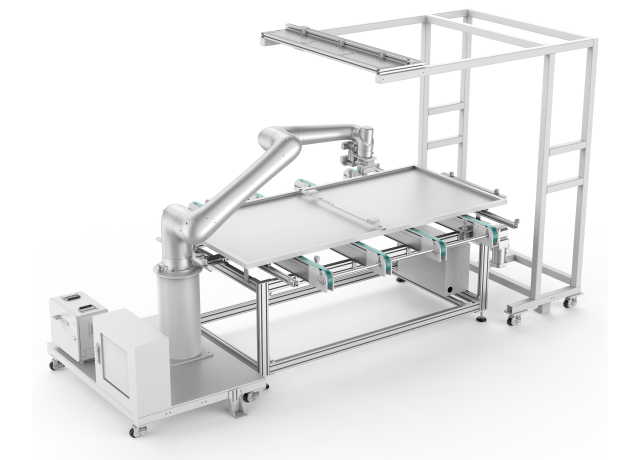

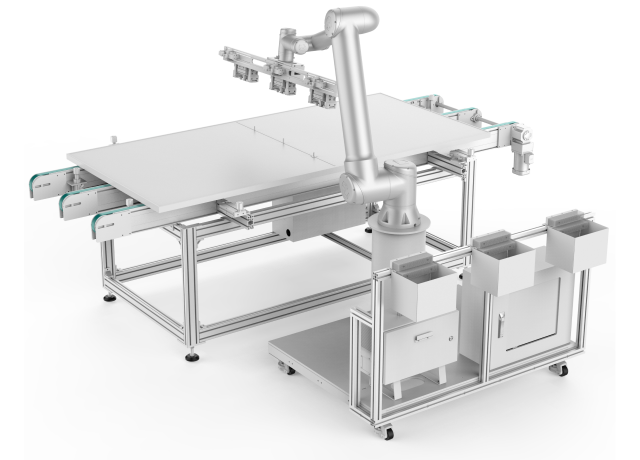

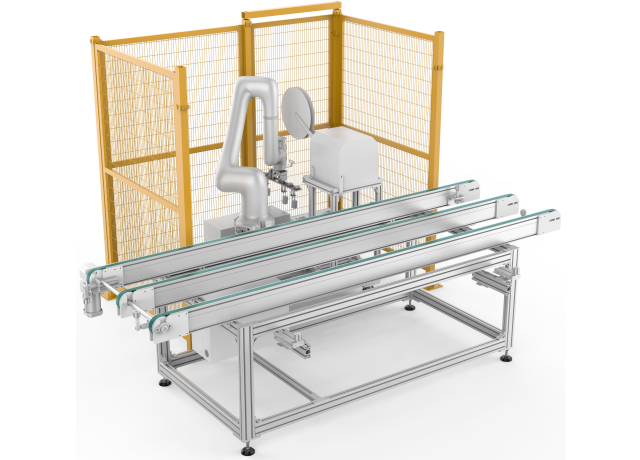

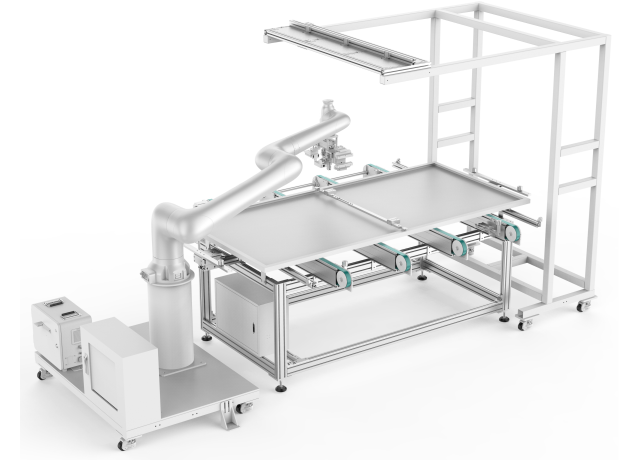

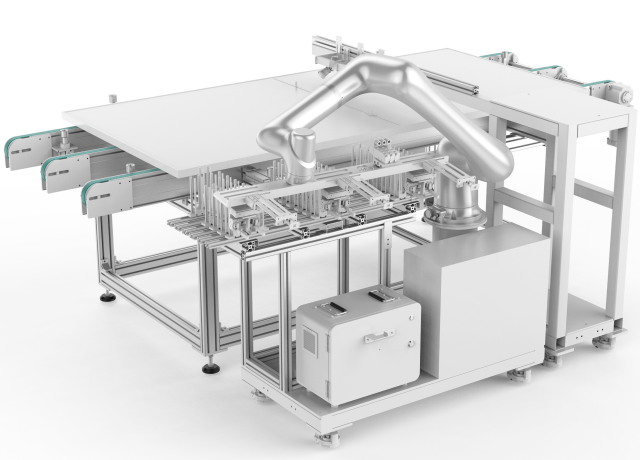

ROBOT PLACING EVA STRIPS

The robot automatically grabs the EVA strip, puts it on theshort side of the module, and fixes it with hot melt after it is placed.

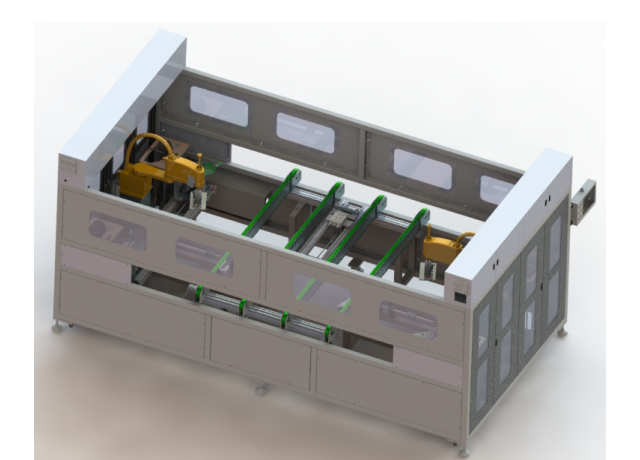

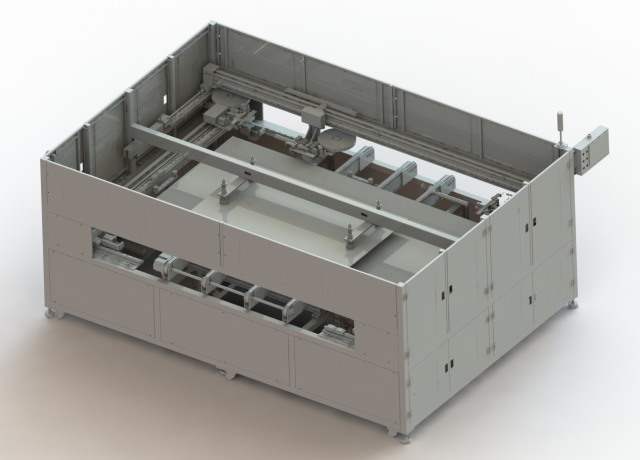

Structural Features

The robotic arm has multiple degrees of freedom, making it more flexible and stable.

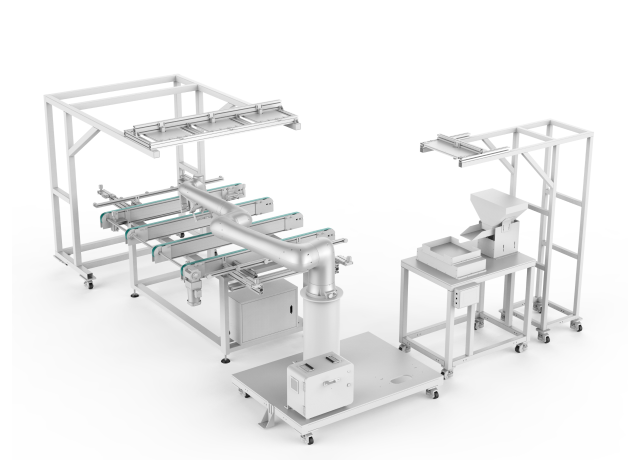

The input trolley is equipped with a circular track, ensuring more precise feeding.

The input trolley can hold multiple EVA strips, reducing the frequency and time required for feeding changes.

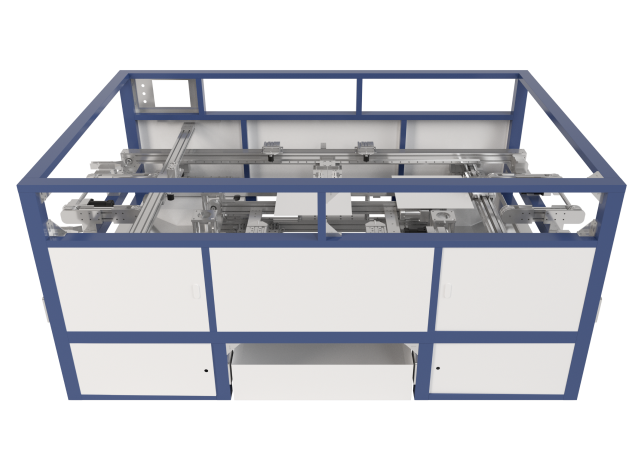

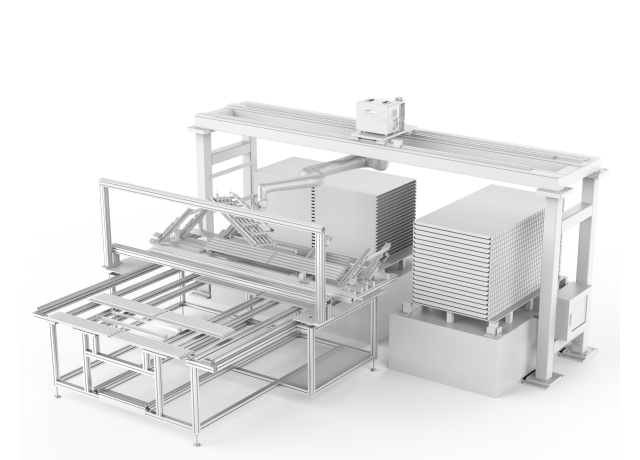

Module transmission and positioning: Variable frequency motor + Synchronous belt + Servo alignment.

The overall structure includes standardized conveyors, placement of EVA strips, picking up EVA strips, fixed structures, and a vacuum system.

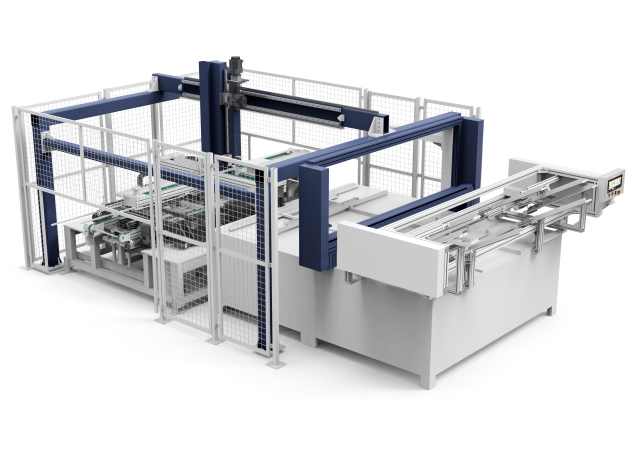

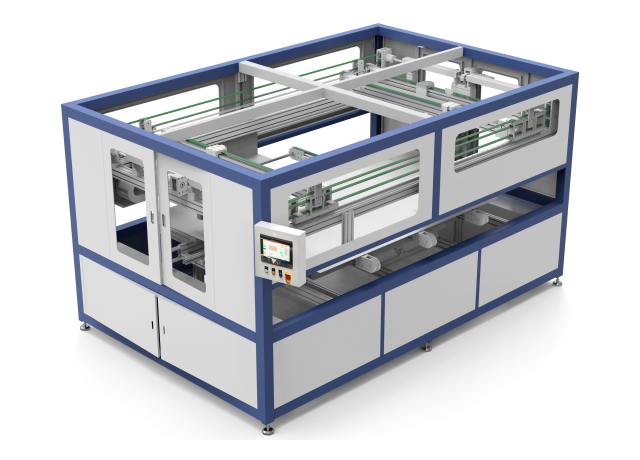

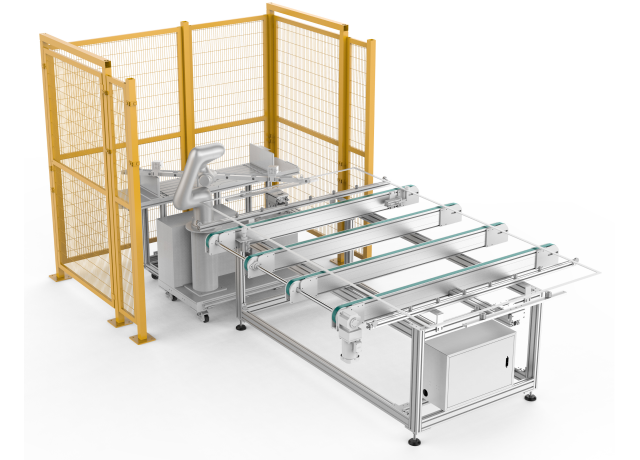

Structural Features

Operating Voltage

AC220V, 50-60Hz, 2KW

Operating Air Pressure

0.6-0.8MPa

Average Air Consumption

≥600L/min

Applicable Module Size

Length (1630-2650mm) x Width (950-1450mm)

Overall Cycle Time

14 seconds

Label Pass Rate

≥99.5%

Rewind Specification

Varies with module size

Drive Mode

Servo Control

Control Mode

PLC+HMI+Servo Control

Pneumatic Components

SMC/Airtac

Module Positioning Accuracy

±1mm Repeated Positioning

Repeat Positioning Accuracy

Grasping Accuracy ±0.5mm

Overall Dimensions

1704*1106*980mm

.png)