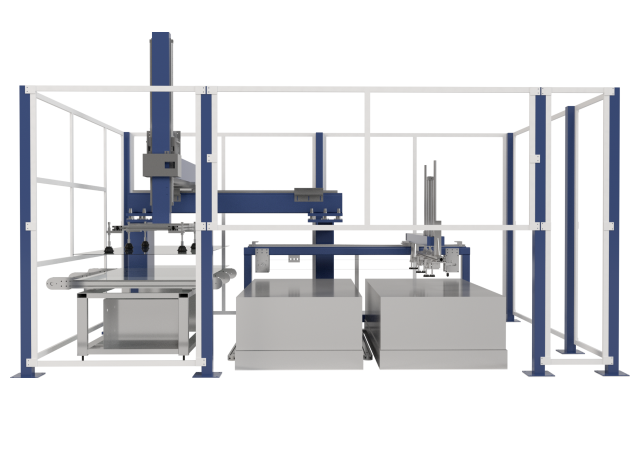

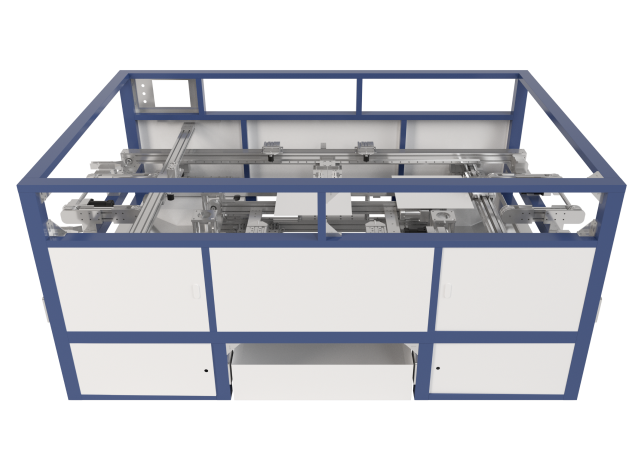

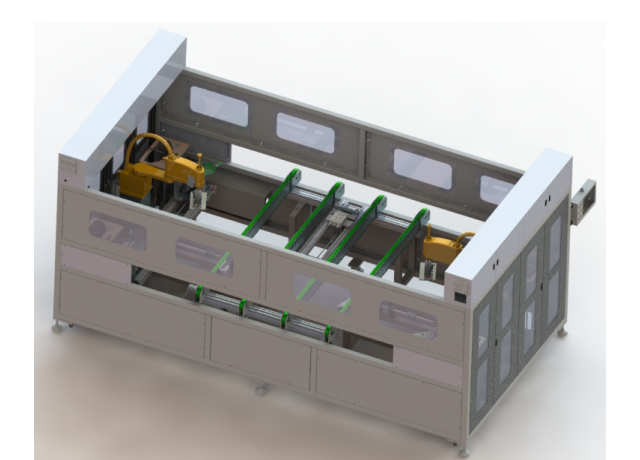

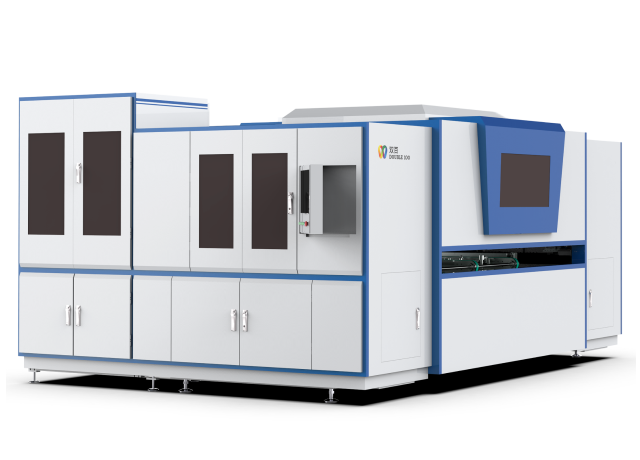

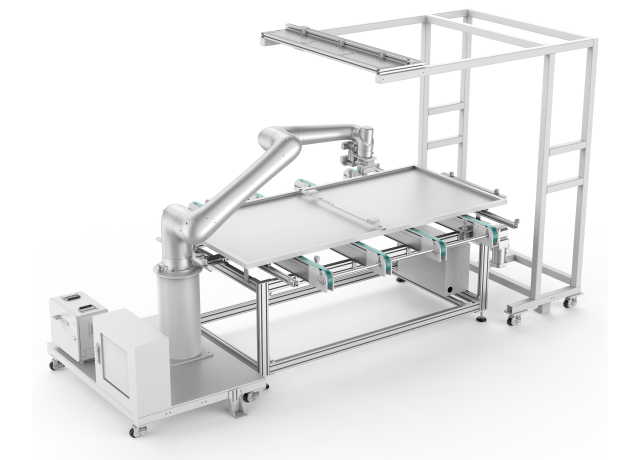

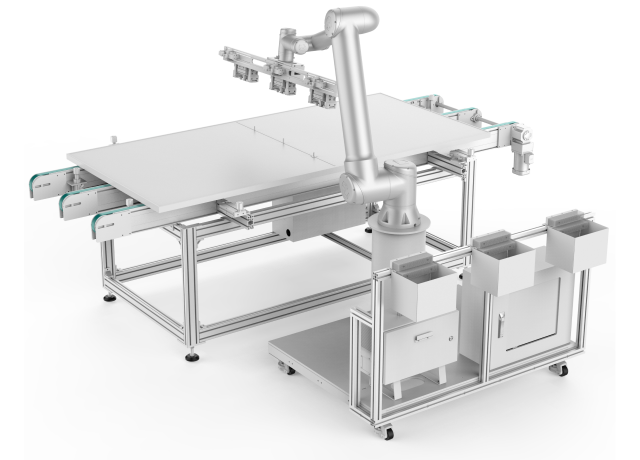

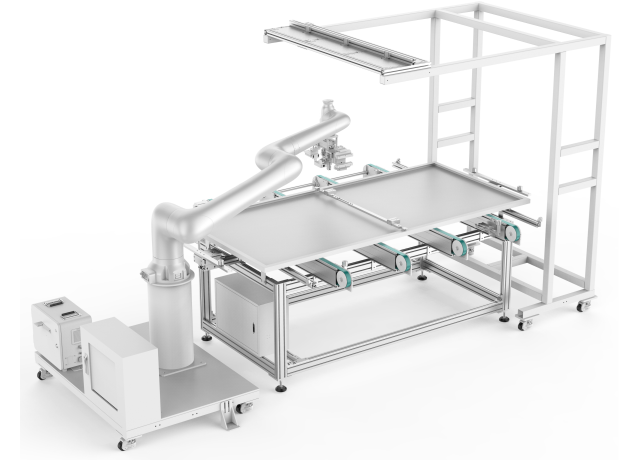

Structural Features

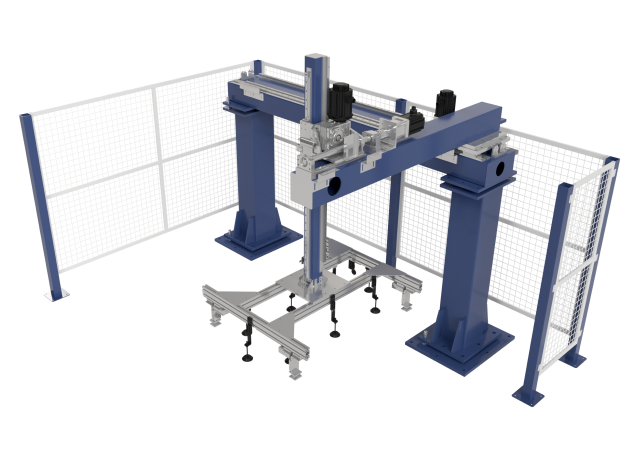

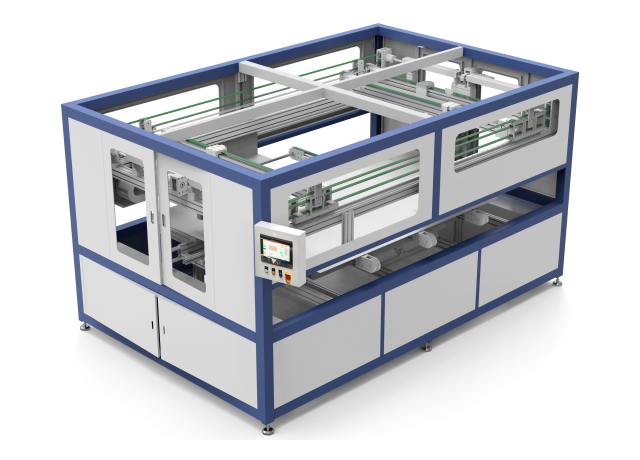

German technical support, heat transfer is contactless and is not affected by contamination.

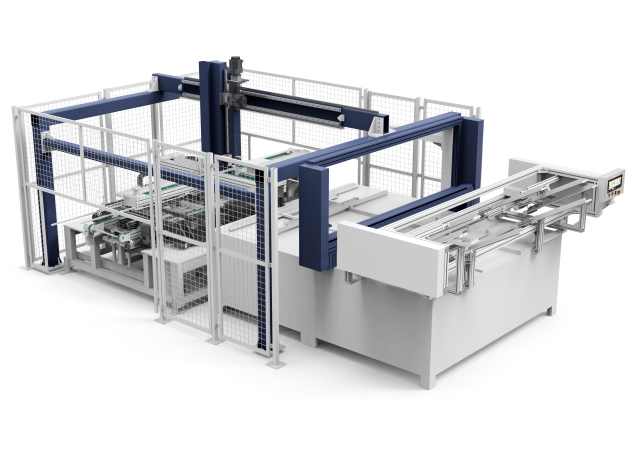

The design of the module can realize different soldering modes for the upper and lower parts of the ribbons. Adjustments to the local module can also achieve soldering for semi-chip modules, junction boxes in the middle, multigrid, and other special modules.

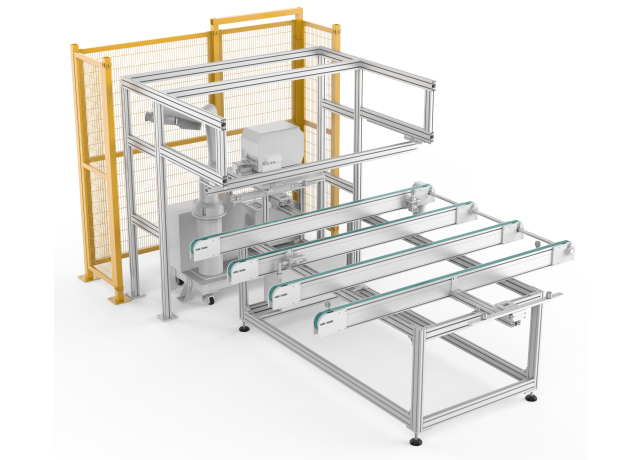

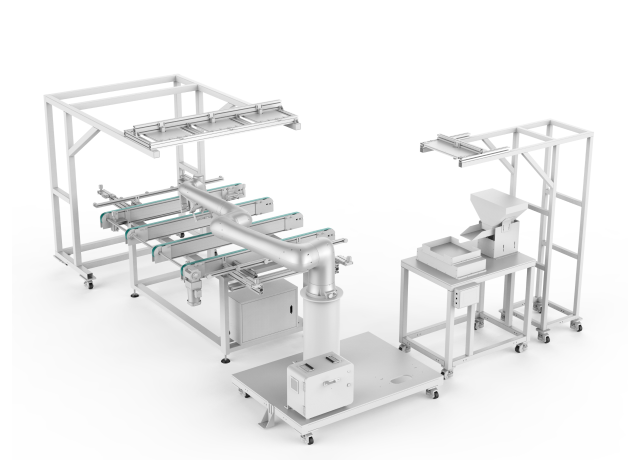

Straight-line and L-type ribbons are produced at each end of the machine, which ensures production efficiency and stability of ribbon production.

The soldering head is made of ceramic material, which greatly improves the service life and significantly reduces maintenance time.

Flux is added automatically, making it more convenient and effective.

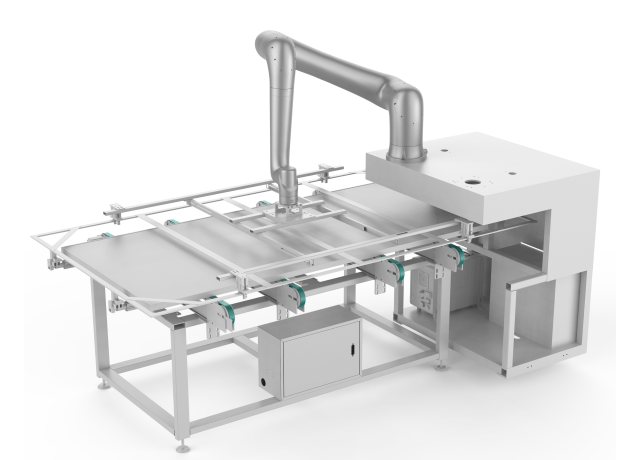

Glass is transferred in two directions according to production line requirements, with a separate PLC controlling the line, unaffected by soldering.

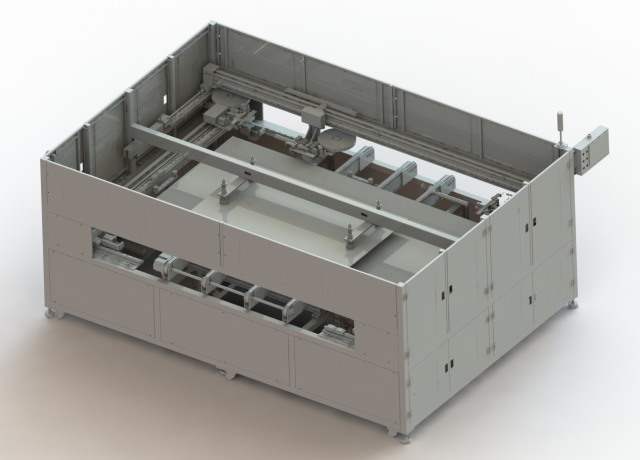

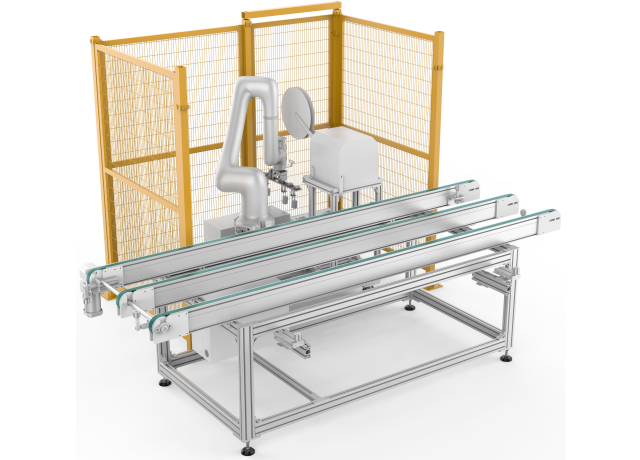

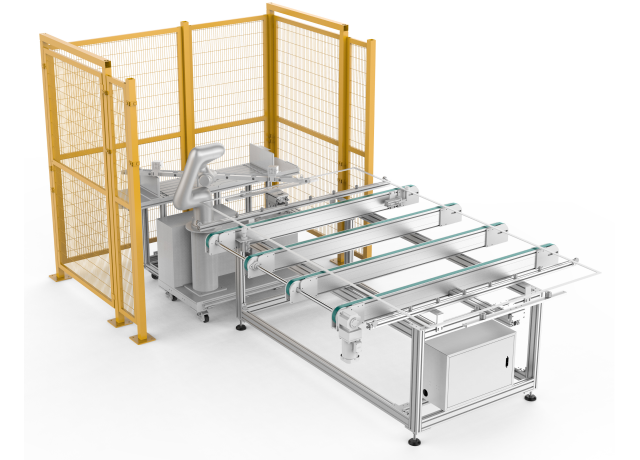

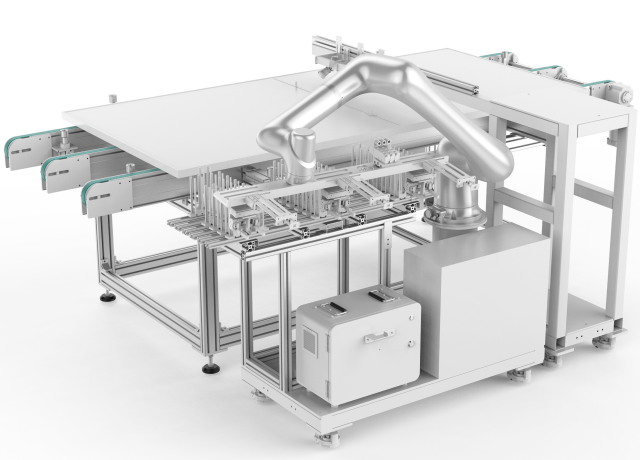

Structural Features

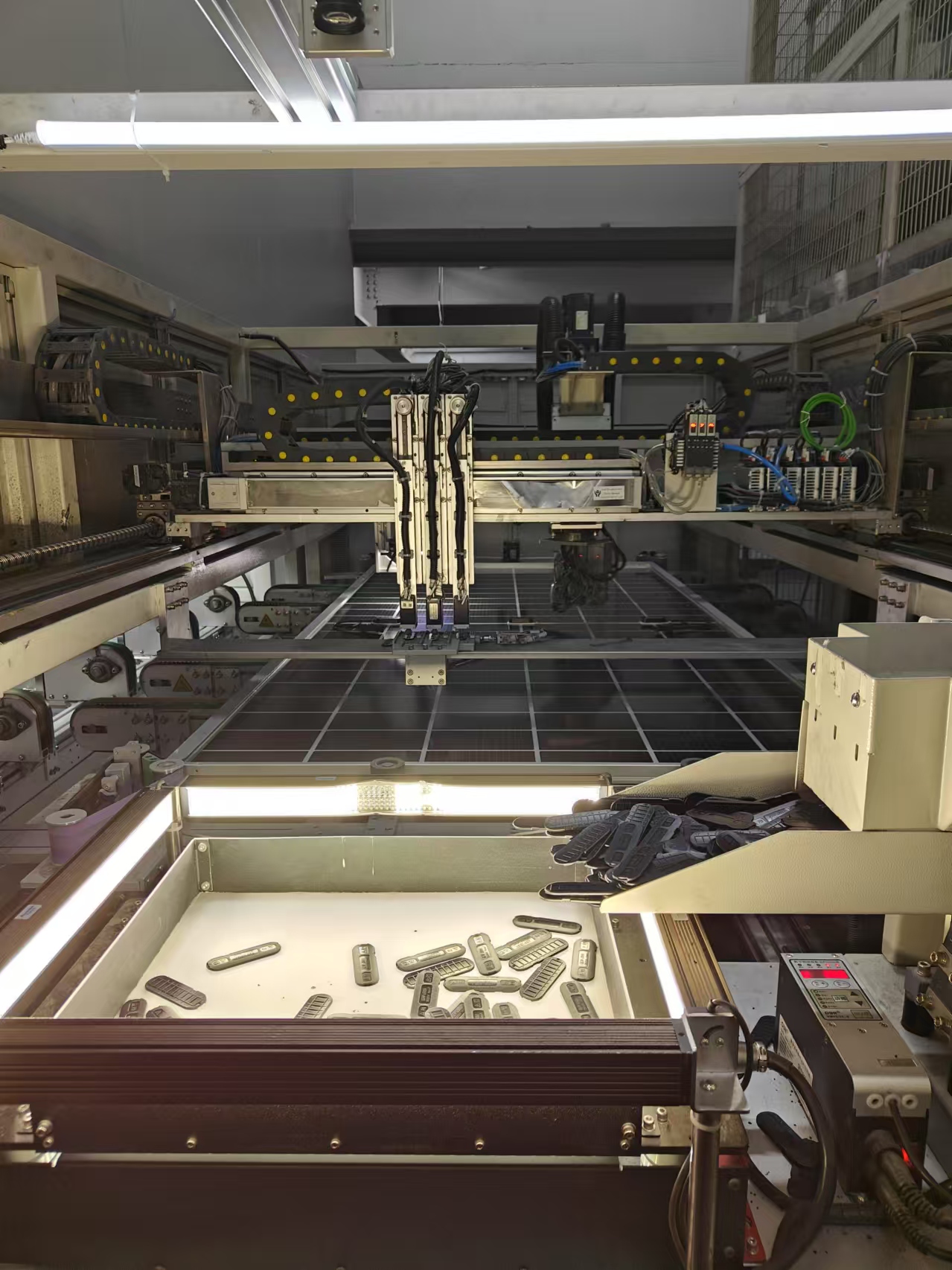

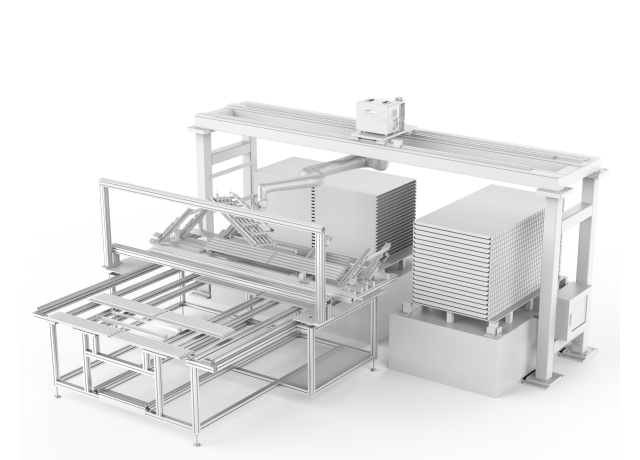

Cell Types

Half cell and Multigrid

Cycle Time

14 seconds

Soldering Method

Induction

Applicable Module Size

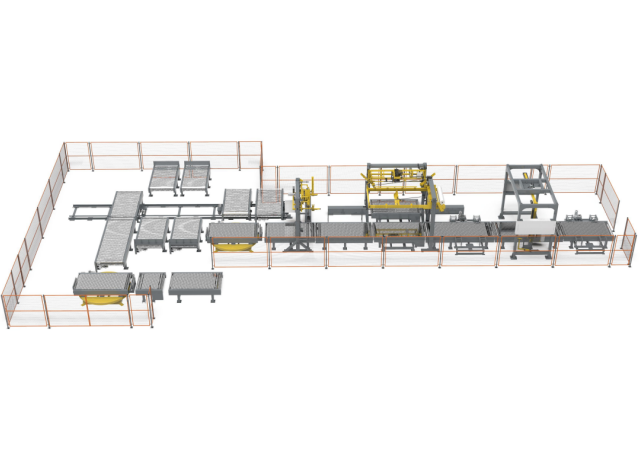

L (1630-2650 mm) × W (980-1450 mm)

Breakage Rate

<0.2% (according to cell quantity)

Leading Wire Angle and Deviation

90°, deviation 2°-3°

After Soldering Tension

≥6N (180° counter pull)

Product Yield

≥99% (according to modules quantity)

Busbar and Ribbons Laying Types

Top or bottom (optional)

Overall Dimensions

5600 × 5000 × 2600 mm

Total Weight

About 6000 kg

Power Supply

AC380V, 3 Phase 5 Lines, 50Hz, 35KW

Working Air Pressure

0.5-0.8 MPa

Average Air Consumption

≥2000 L/min

.png)