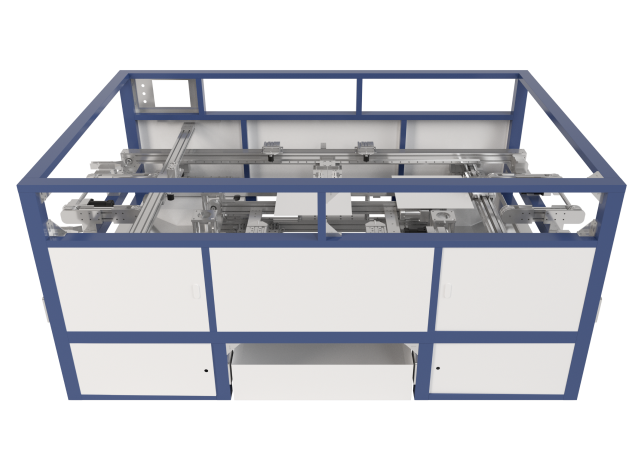

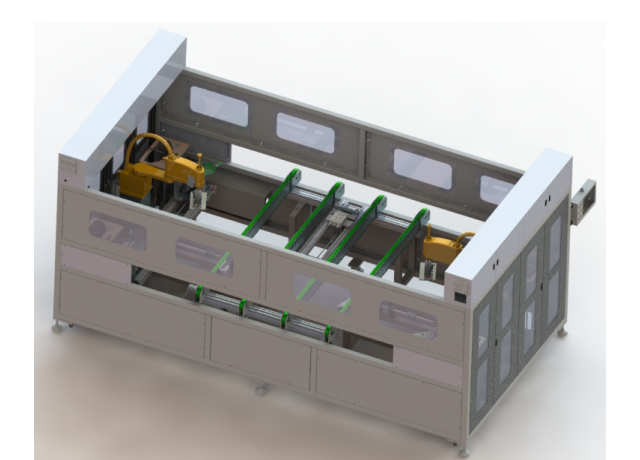

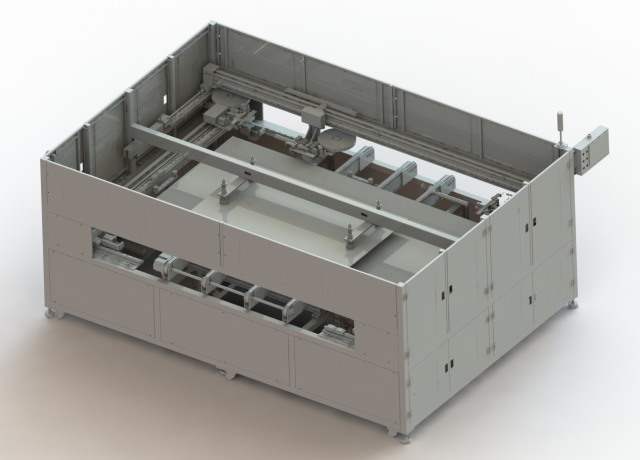

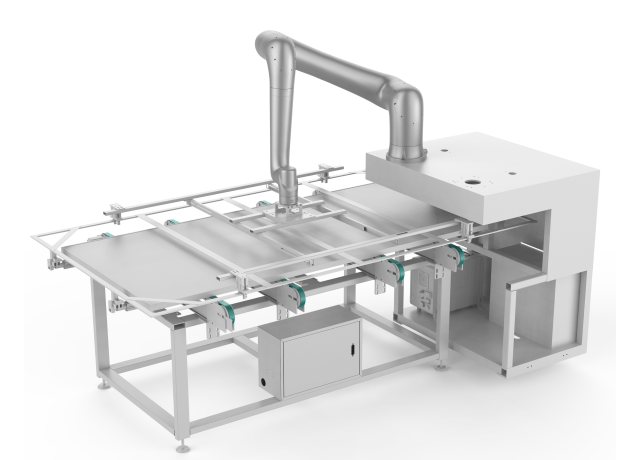

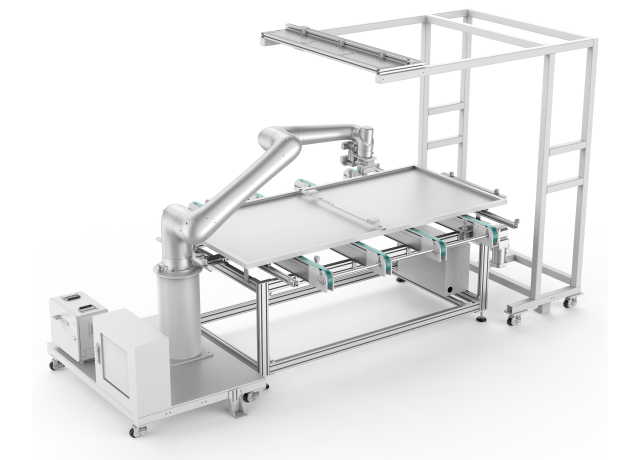

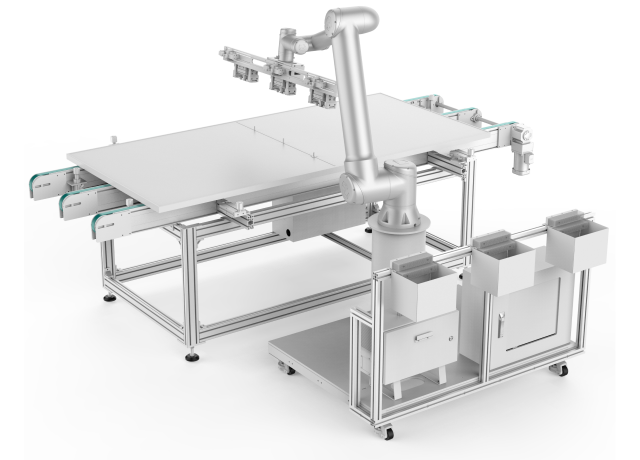

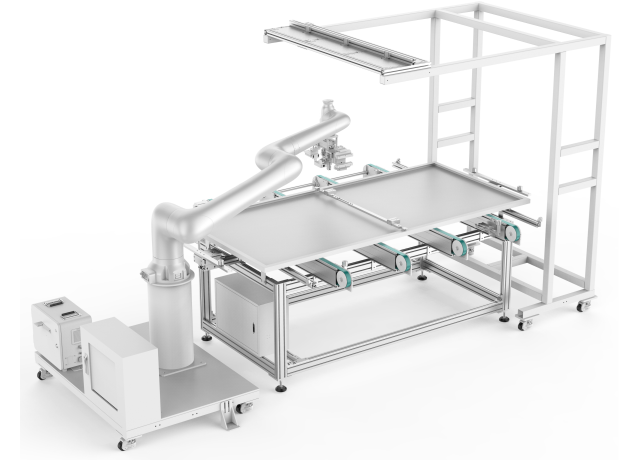

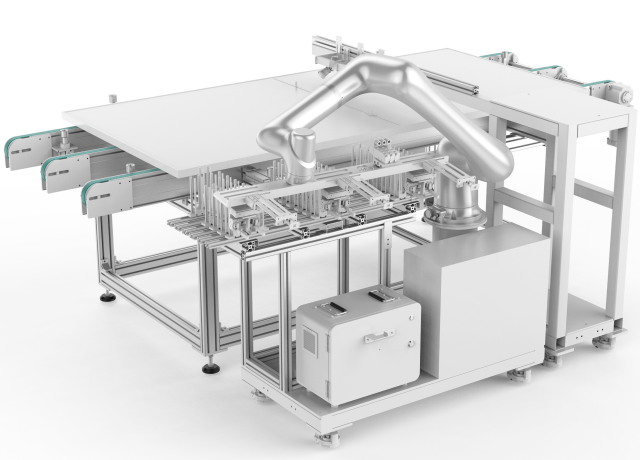

Structural Features

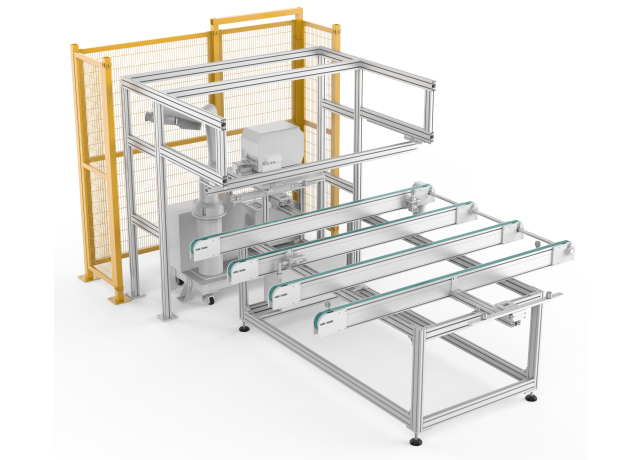

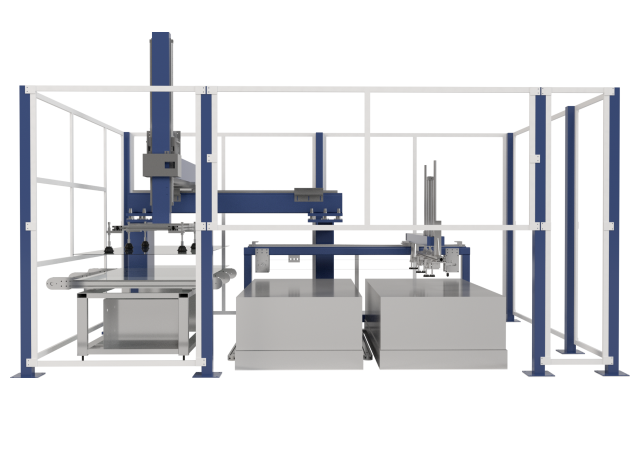

The overall structure includes a glass transport alignment unit, a tape edge sealing module, a servo screw mechanism, and a vacuum system.

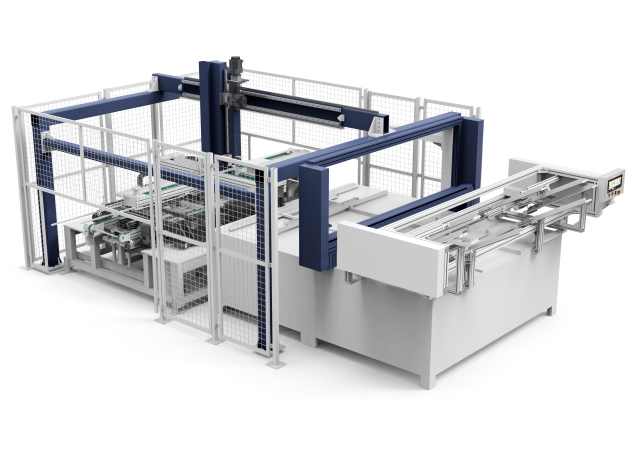

The servo motor combined with the module drives the edge banding mechanism, featuring fast operation and high precision.

The edge sealing system includes tape fixation mechanism, tape sealing and sticking mechanism, sealing mechanism, and flattening mechanism.

Using horn rollers to roll the tape can flatten the tape, preventing rigid contact and avoiding the possibility of battery breakage and cracking.

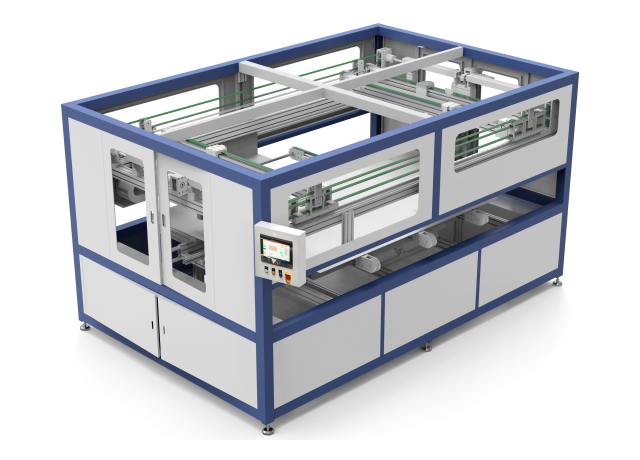

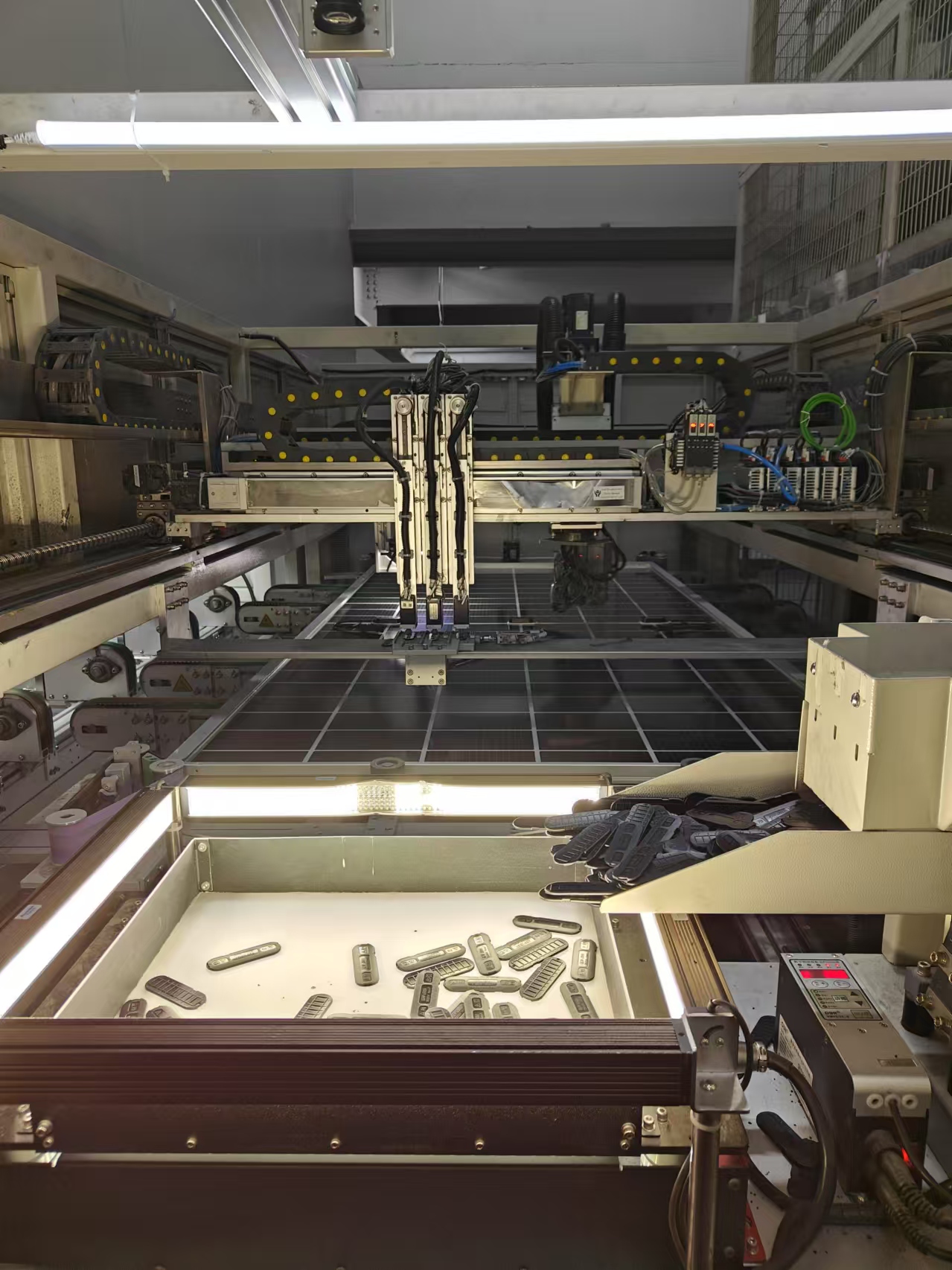

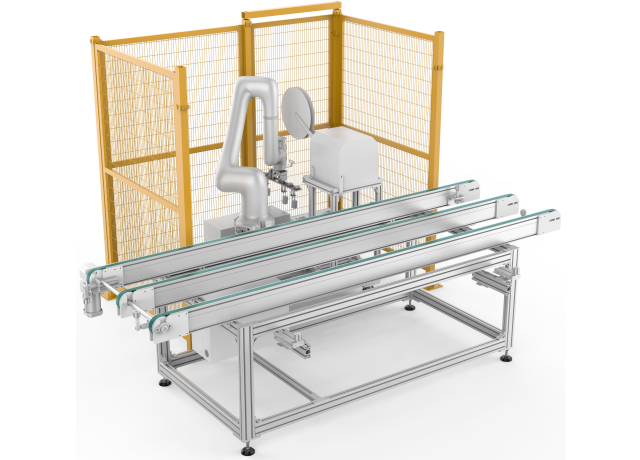

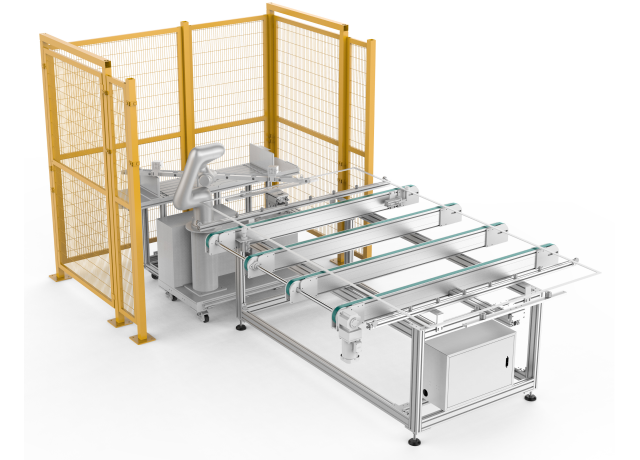

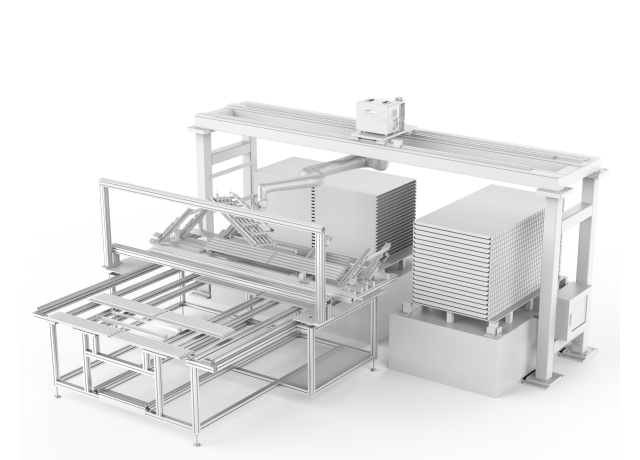

Structural Features

Operating Voltage

AC380V, Three-Phase Five-Wire, 50/60Hz

Rated Power

4KW

Working Air Pressure

0.6-0.8MPa

Average Air Consumption

≥200L/min

Module Size

L(1630-2650mm) x W(950-1450mm)

Positioning Accuracy

±1mm

Tape Replacement Time

≤180 seconds

Integrated Cycle Time

14 seconds

Yield

≥99%, No Creases, No Bubbles, No Cracks

Alignment Method

Four-Side Alignment

Tape Length

≤400m

Tape Width

30-40mm

Overall Dimensions

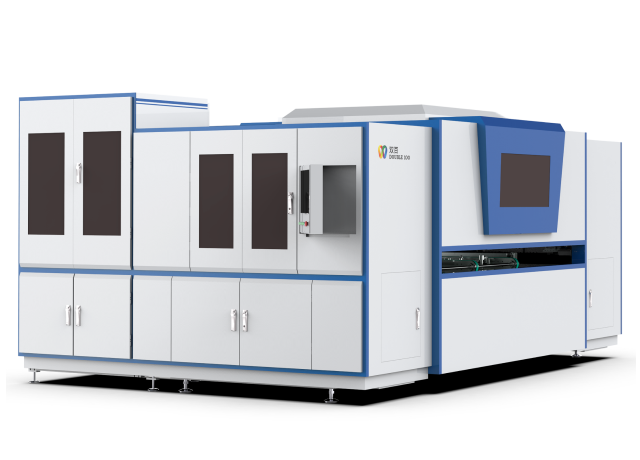

3700*2500*1650mm

Total Weight

Approximately 2000kg

.png)