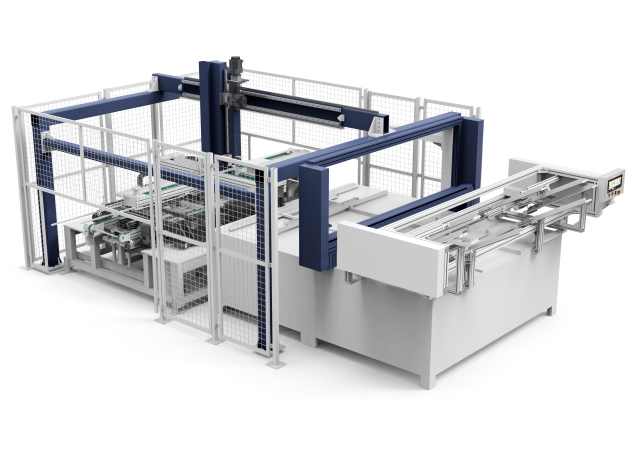

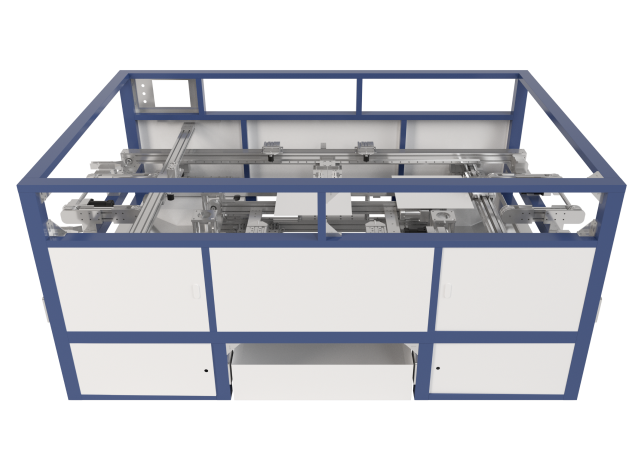

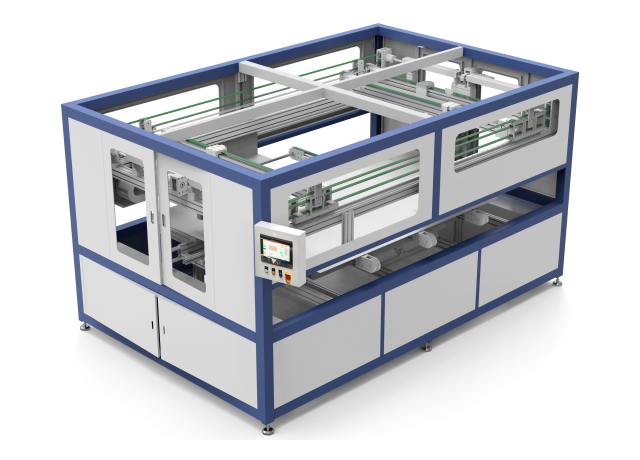

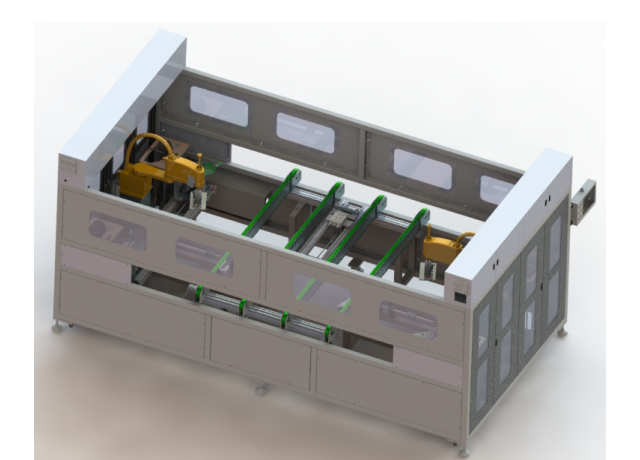

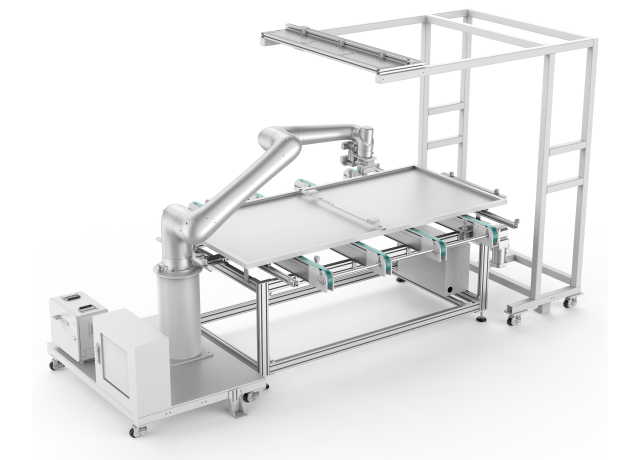

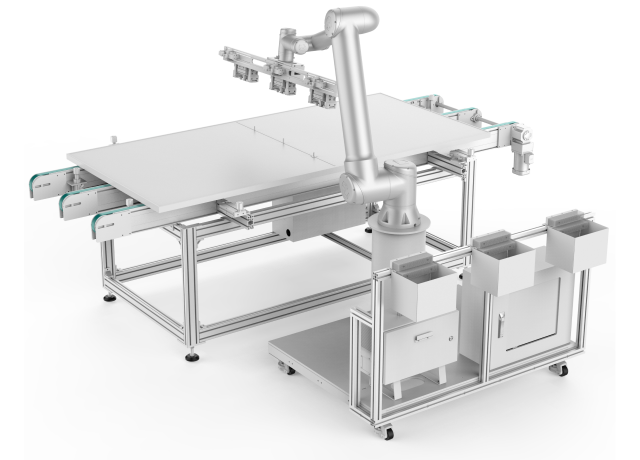

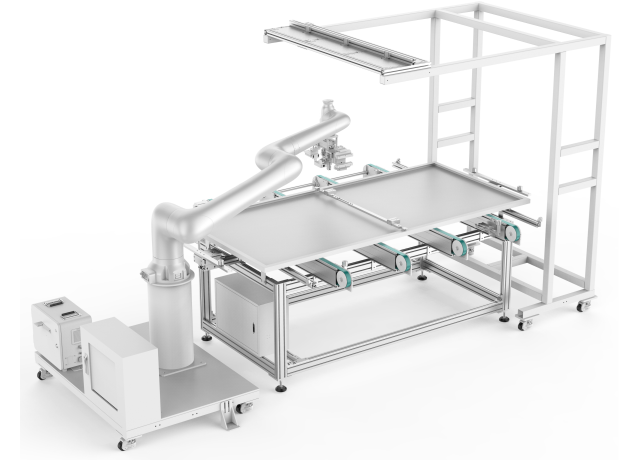

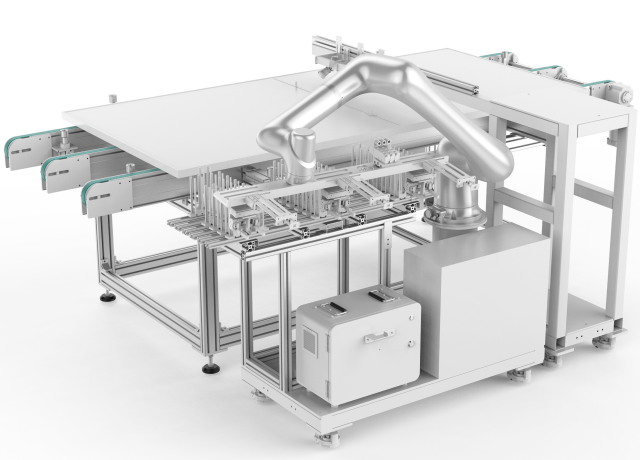

Structural Features

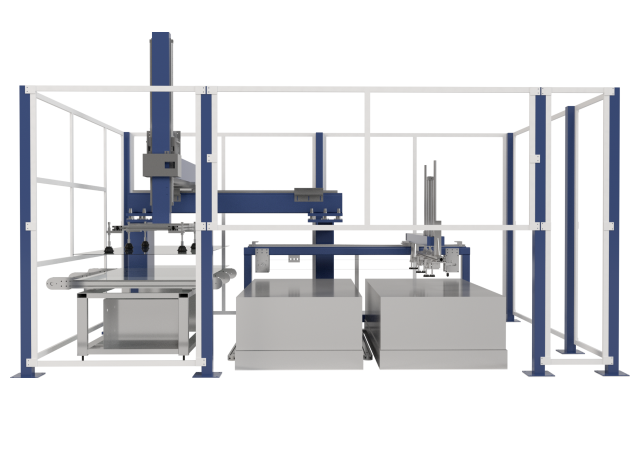

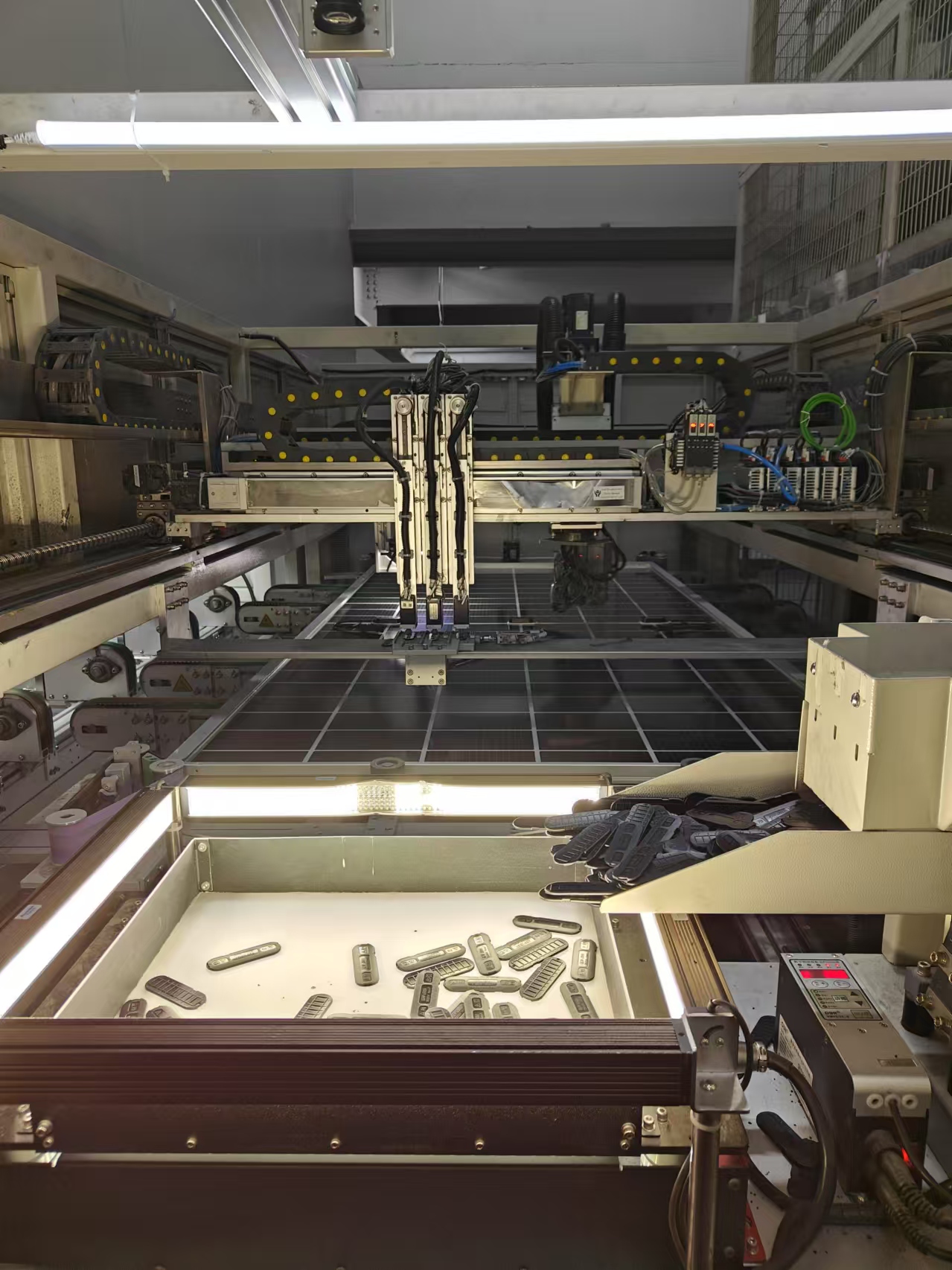

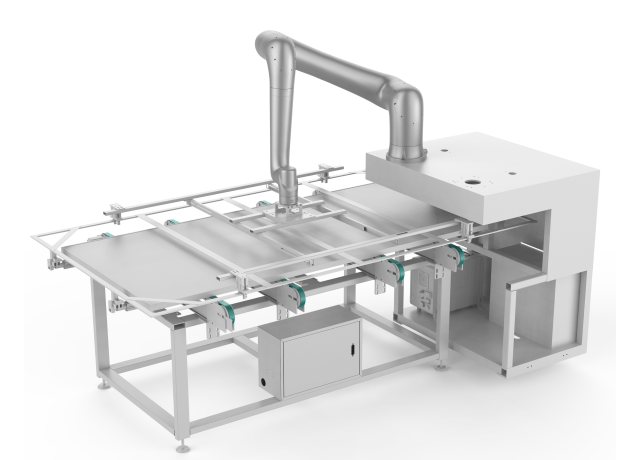

The machine composed by the PLC,servo motor and air control system, digital sensor,easy to operate ,highin automatic and stable running.

Cutting system: cutting knife by servo motor control, up and down blade. The blade is made by SH-9 high speed steel.

Way of connection EVA: continuous producing, by hot melt connection Back sheet: continuous producing, by adhesive tape connection.

Inputting: EVA: stable tension control to input, Back sheet: auto tension control to input

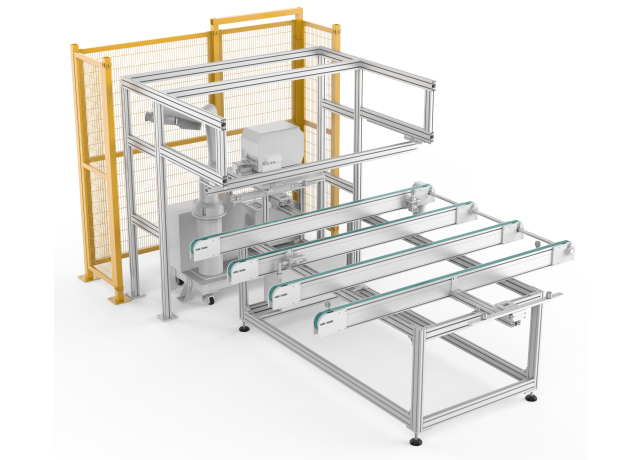

Laying: EVA: the system adopts the auto outlet way, the machine hand auto pack the material after cutting.The Synchronous Control Technology is used to isolate the plate and battery and flat them in reverse direction.

Loading :by electrical loading, one worker can operate.

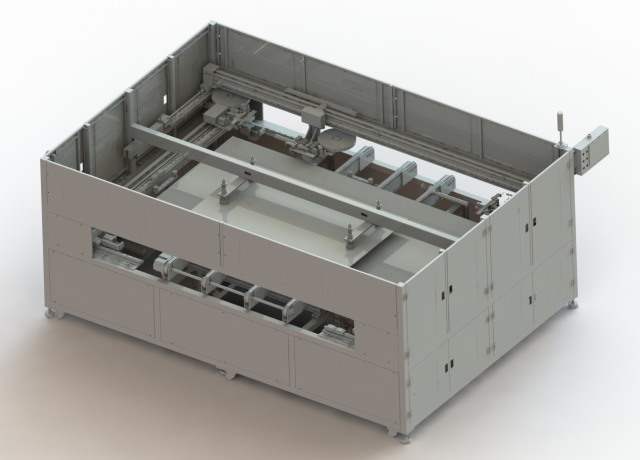

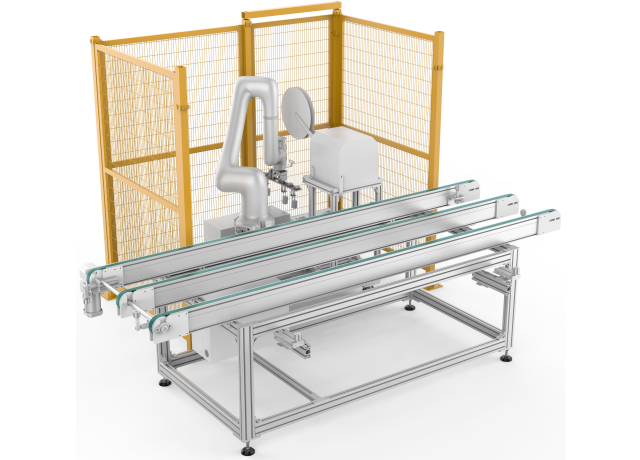

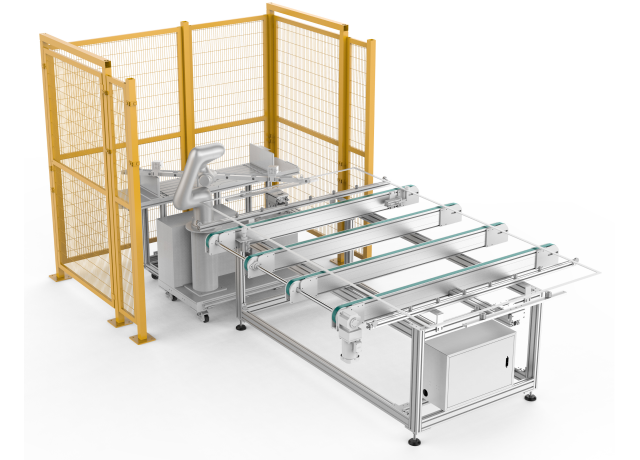

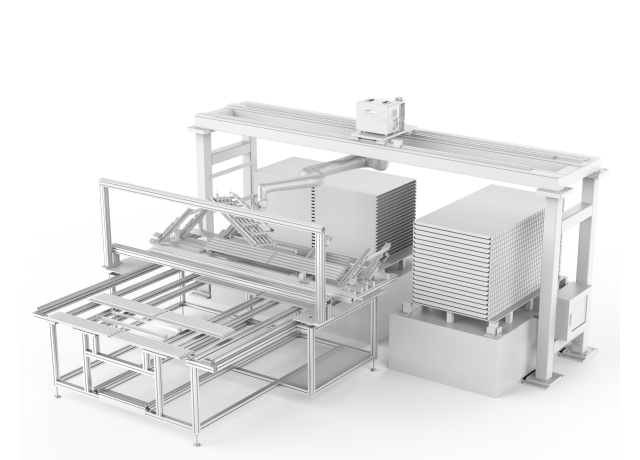

Structural Features

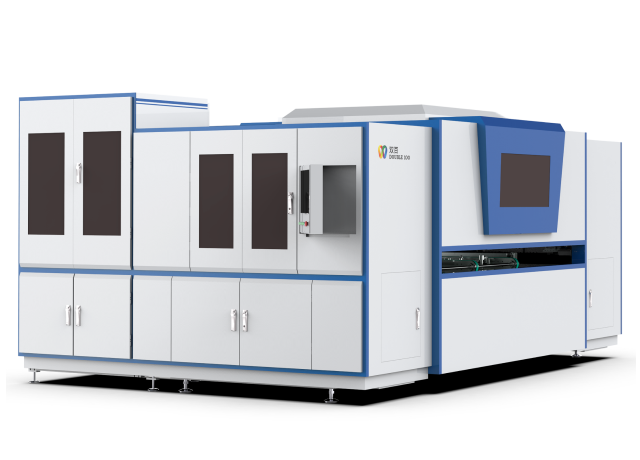

Working Working voltage

AC400V,3 Phase 5 Lines,50-60Hz 4KW

Working air pressure

0.6-0.8MPa

Average Air Consumption

≥80L/min

Applicable Module Size

L(1630-2650mm)xW(950-1450mm)

Max. Roll diameter

roll diameter:400-850mm,TPTlength:1200m EVA length: 800m

Max. Roll Weight

≥1000kg

Accuracy

EVA±2mm,TPT±1mm

Blade Service Period

500-10005-10 million times

Loading Time

≤ 3min

Integrated Tact

14S

Punch Change Time

≤5min

Overall Dimensions

5200x2170x1800mm

Total Weight

About 2500kg

.png)