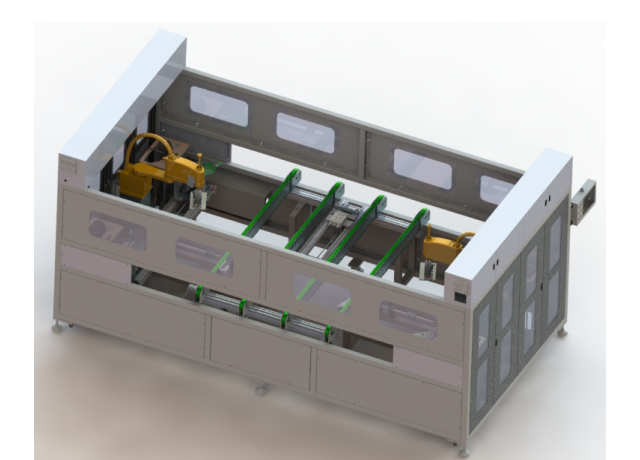

Structural Features

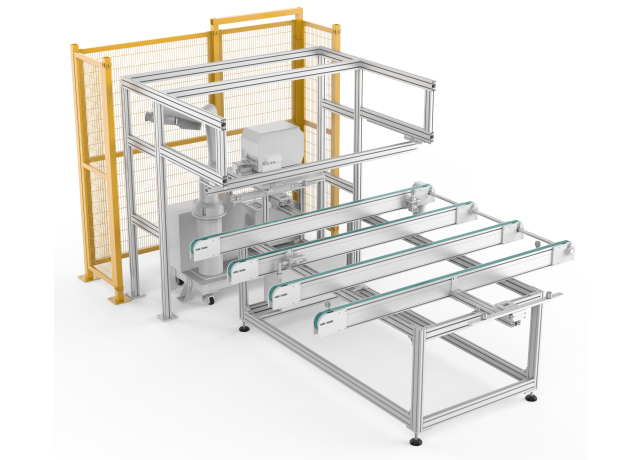

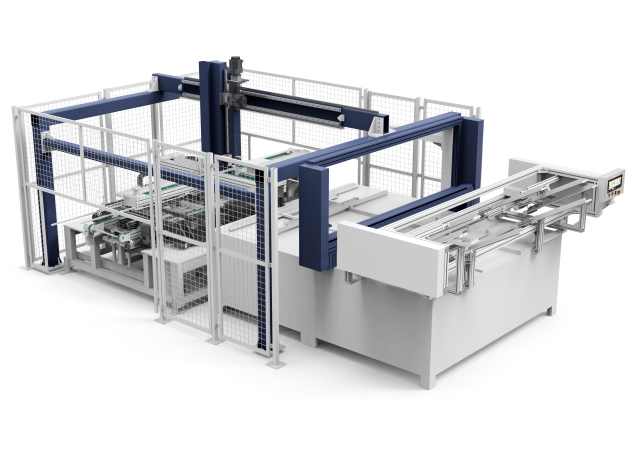

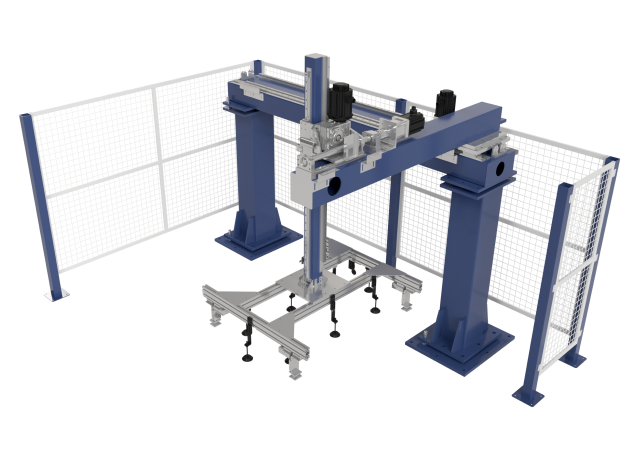

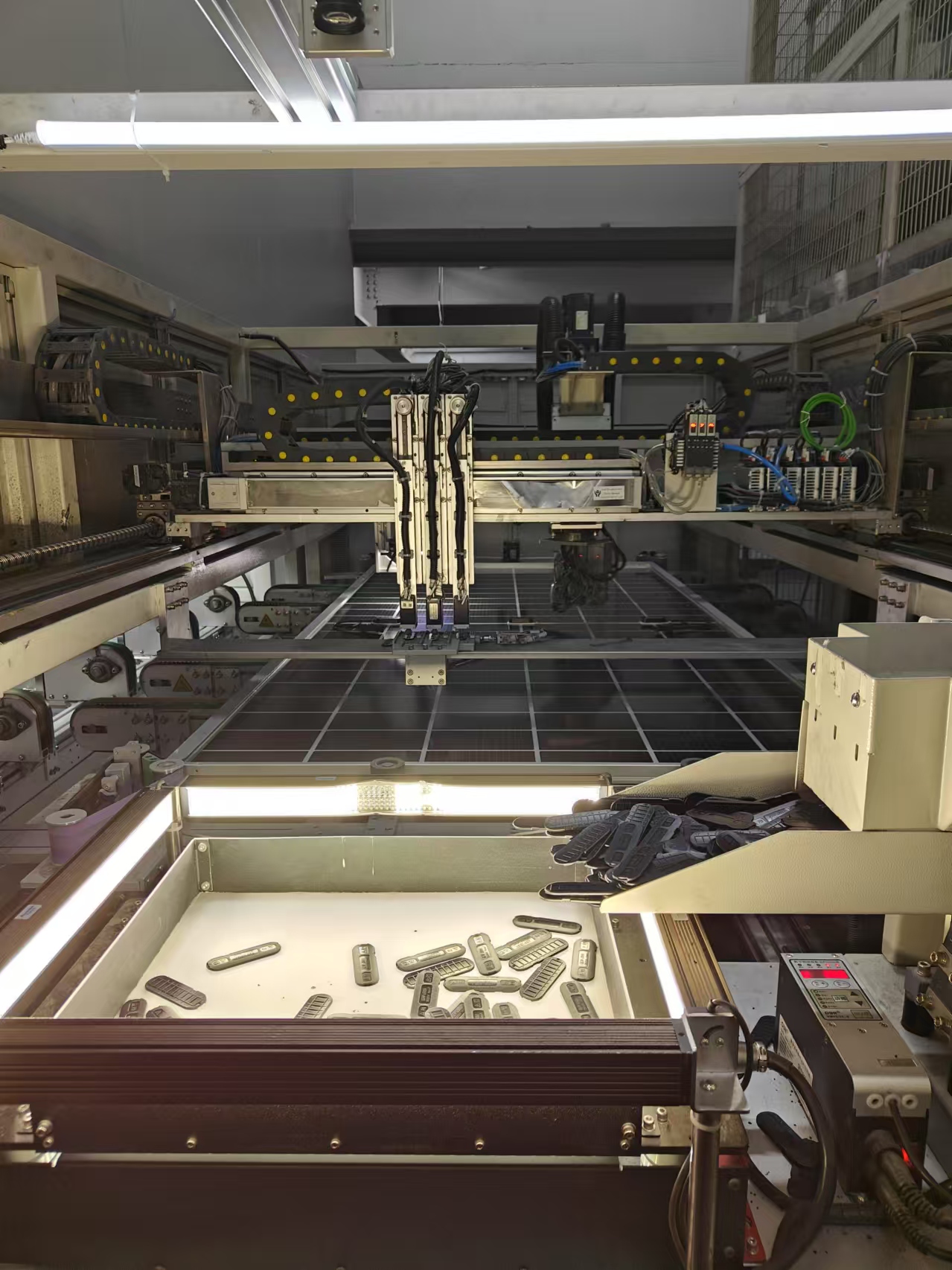

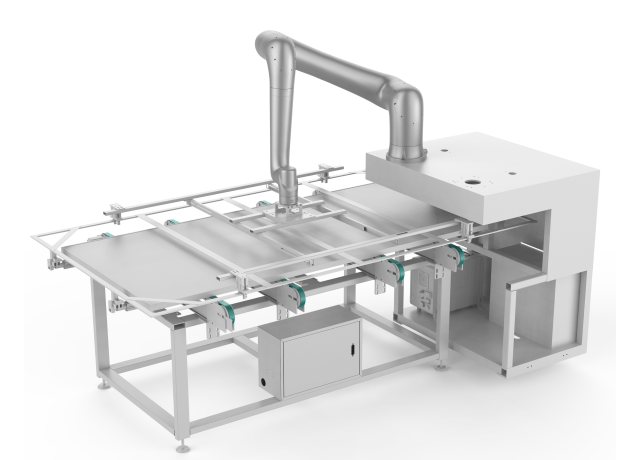

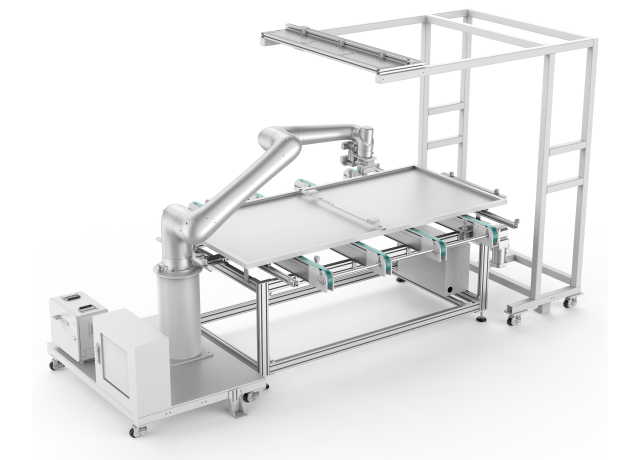

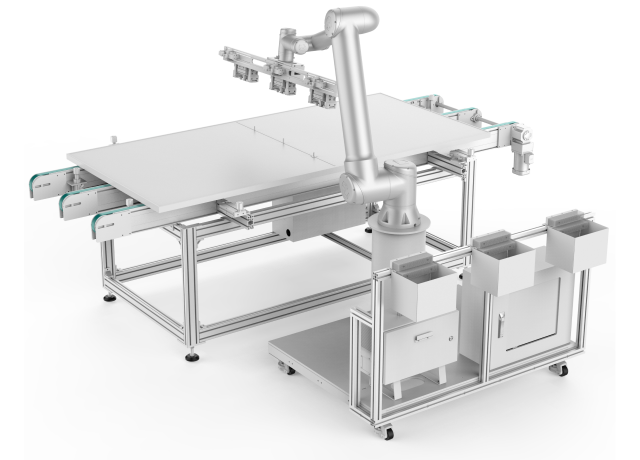

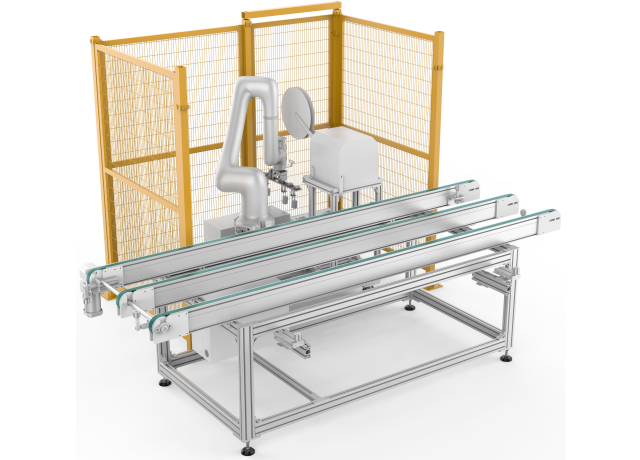

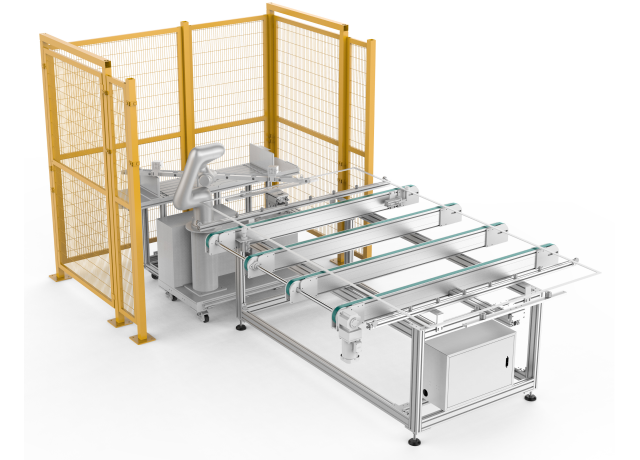

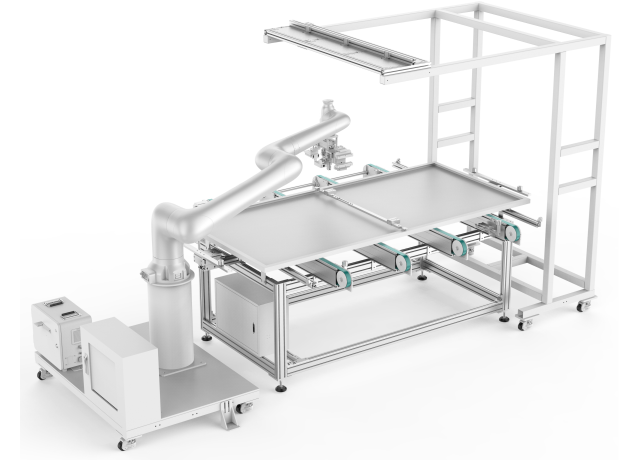

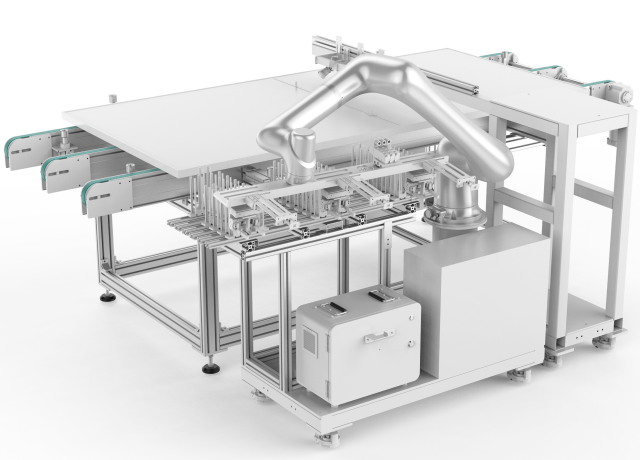

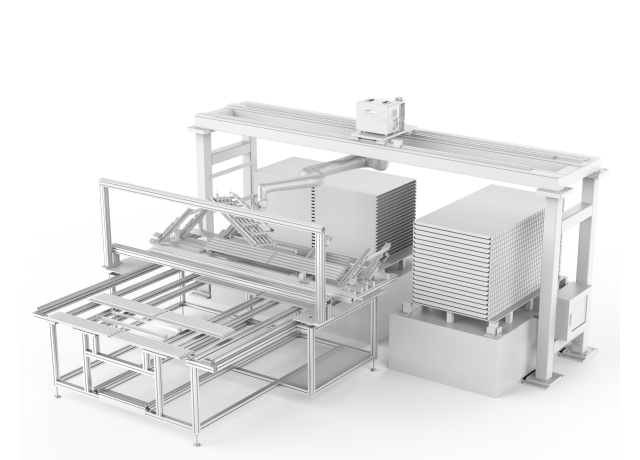

Frame Structure: The main structure is reinforced by the overall welding of square pipes and the assembly of profiles.

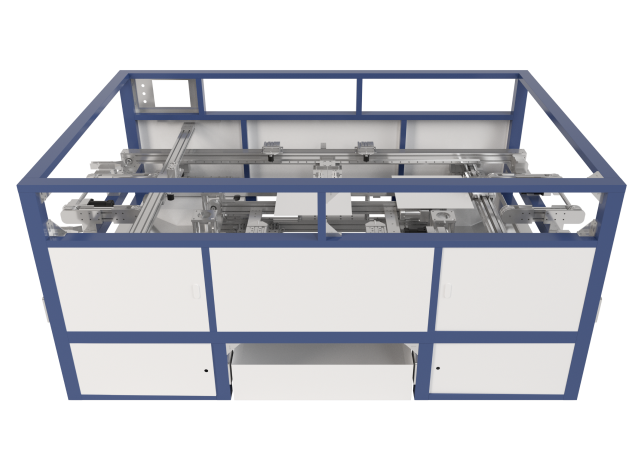

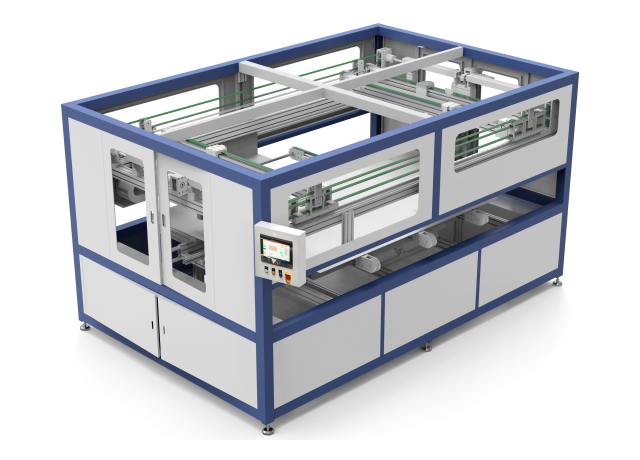

Transmission System: Module input direction: Long side input, with four polyurethane belts for input. The transfer motor uses frequency control and is equipped with sensors to automatically detect the input and output of the module.

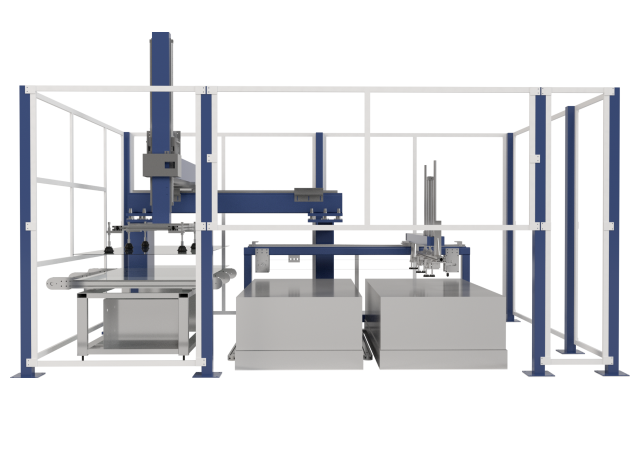

Soldering System: The soldering system adopts a tripartite structure, with each soldering head having independent X, Y, and Z axis movements to ensure the optimal soldering position. It includes a longitudinal movement mechanism to achieve full coverage of the soldering head position within the module range.

Vision System: CCD high-definition industrial camera with a pixel range from 5 million to 10 million to achieve precise positioning of the junction box.

Laser Soldering System: Uses laser soldering, no material loading required.

Control System: The control system can interact with the MES system to upload equipment information.

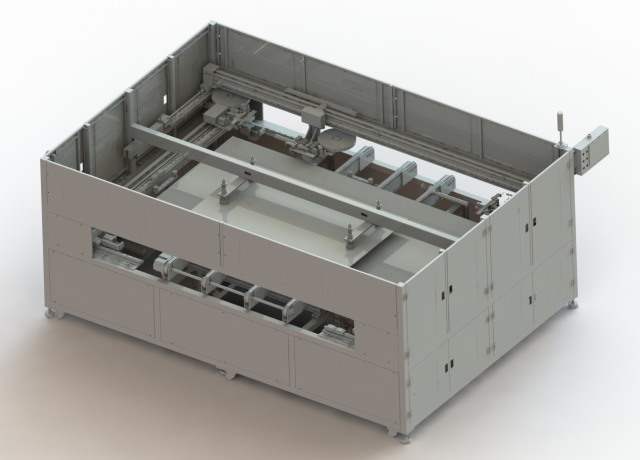

Structural Features

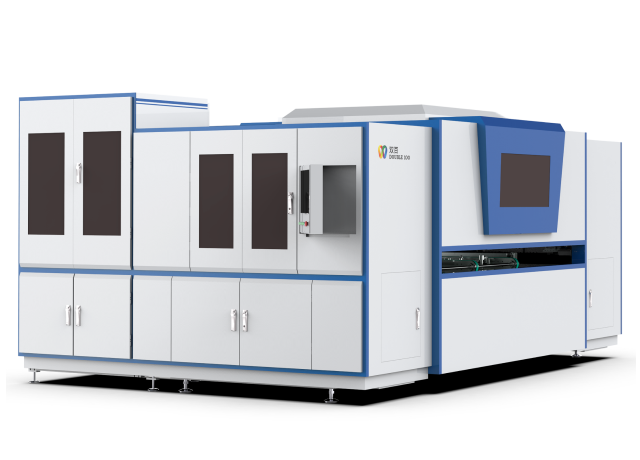

Applicable Module Size

L (1630-2650mm) x W (950-1450mm)

Soldering Method

Automatic Laser Soldering

Positioning Accuracy

Visual Positioning

Yield

≥99.6%

Integrated Cycle Time

14 seconds

Soldering Temperature

0-500°C ±5°C

Soldering Tension

≥80N

Type Switching Time

Automatic Switching

Working Voltage

AC380V, 3-Phase 5-Wires, 50Hz, 20KW

Air Pressure

0.6-0.8MPa, 400L/min

Overall Dimension

3150*1800*2060mm

.png)